I recently had my well water tested by a local water treatment company. We moved into the house about 2 years ago and have always had scale in the dishwasher and some brown staining in the toilets (much worse in the tanks). We are finally looking to fix these issues and based on feedback I've seen in many of the other posts here, I welcome any input/recommendations from the pros on this forum. Here is some more background information and the water test results I received.

- The previous Owner had a new well installed in 1982. The total depth of the well is 945 feet. The paperwork says the pump yield is 6 gpm. I calculated a little over 5 gpm using the bucket method right after the pressure tank.

- The previous Owner had a WX250 pressure tank (40/60), then a Culligan P5A Standard Duty Sediment Filter (5 microns), then a resin tank with no control valve and an unknown media. Picture of the set-up and a dirty filter attached. The filter gets coated in a brown slimy film after awhile. I've been changing it every ~3 months.

- All plumbing is 3/4"

- We are a family of 4 (including 2 toddlers currently) with 2.5 baths

Results at Pressure Tank (untreated):

Hardness: 13 gpg

pH: 7.51

Alkalinity: 4.68 gpg

Chlorides: 14 gpg

TDS: 624 ppm

Iron: 3.32 ppm

Turbidity: 44.2 ntu

Sulphates: 3.39 gpg

Iron Algaes: Light

Results at Kitchen:

Hardness: 13 gpg

pH: 7.55

Alkalinity: 4.68 gpg

Chlorides: 14 gpg

TDS: 641 ppm

Iron: 0.12 ppm

Turbidity: 2.09 ntu

Sulphates: 3.51 gpg

Iron Algaes: None

1. I'm not sure if the test results above are detailed enough for recommendations. I've seen KAR Labs Kit-90 and NTL Well-Check recommended here. If additional testing is required, the Kit-90 looks to be more reasonably priced. Is there any reason not to use this one? Also, where should the sample be taken from if needed?

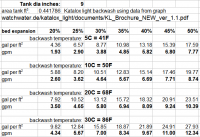

2. Whatever solution is recommended, I am concerned about the backwash rate required by the treatment equipment vs. what our well pump produces. Also concerned about the pressure drop through the entire system.

3. The water treatment company recommended an upgraded filter (4"x10"), to leave the unknown resin tank in place (attributed it to iron removal based on results), and then add a 48k water softener with a Res-Up Kit. I definitely do not want to leave the unknown tank in place as there is no way to backwash, clean, replace the media. I assume it will just fail on its own overtime.

Let me know if you need additional information and thanks in advance for your help/time!

- The previous Owner had a new well installed in 1982. The total depth of the well is 945 feet. The paperwork says the pump yield is 6 gpm. I calculated a little over 5 gpm using the bucket method right after the pressure tank.

- The previous Owner had a WX250 pressure tank (40/60), then a Culligan P5A Standard Duty Sediment Filter (5 microns), then a resin tank with no control valve and an unknown media. Picture of the set-up and a dirty filter attached. The filter gets coated in a brown slimy film after awhile. I've been changing it every ~3 months.

- All plumbing is 3/4"

- We are a family of 4 (including 2 toddlers currently) with 2.5 baths

Results at Pressure Tank (untreated):

Hardness: 13 gpg

pH: 7.51

Alkalinity: 4.68 gpg

Chlorides: 14 gpg

TDS: 624 ppm

Iron: 3.32 ppm

Turbidity: 44.2 ntu

Sulphates: 3.39 gpg

Iron Algaes: Light

Results at Kitchen:

Hardness: 13 gpg

pH: 7.55

Alkalinity: 4.68 gpg

Chlorides: 14 gpg

TDS: 641 ppm

Iron: 0.12 ppm

Turbidity: 2.09 ntu

Sulphates: 3.51 gpg

Iron Algaes: None

1. I'm not sure if the test results above are detailed enough for recommendations. I've seen KAR Labs Kit-90 and NTL Well-Check recommended here. If additional testing is required, the Kit-90 looks to be more reasonably priced. Is there any reason not to use this one? Also, where should the sample be taken from if needed?

2. Whatever solution is recommended, I am concerned about the backwash rate required by the treatment equipment vs. what our well pump produces. Also concerned about the pressure drop through the entire system.

3. The water treatment company recommended an upgraded filter (4"x10"), to leave the unknown resin tank in place (attributed it to iron removal based on results), and then add a 48k water softener with a Res-Up Kit. I definitely do not want to leave the unknown tank in place as there is no way to backwash, clean, replace the media. I assume it will just fail on its own overtime.

Let me know if you need additional information and thanks in advance for your help/time!