boulderbri

New Member

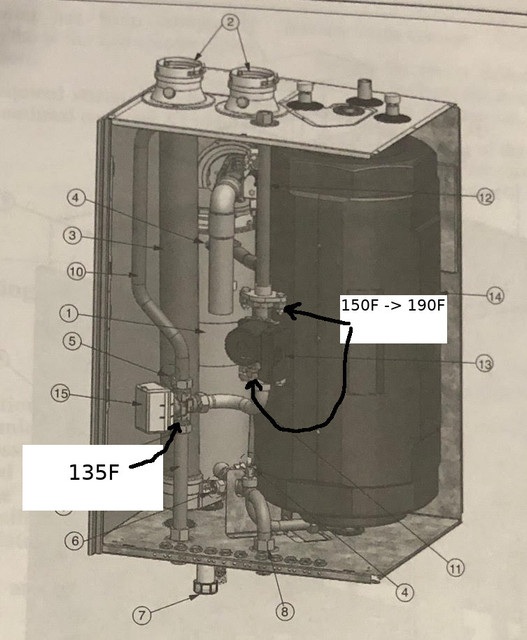

Hi - I have a TT Prestige Solo 110 with the TT Phase 3 Indirect Fired Water Heater. I live in Granby, Colorado at around 8600 feet altitude. The night temps get down to around 0*.

I've been trying to figure out why we aren't getting the same heat as before (a little chilly in the morning). By early day, things have caught up. Settings are all factory default except for the CH Target Temp is 170* instead of the 186* and the pressure is 12 PSI, which is recommended in the manual for residential.

In the morning, when several zones are requesting heat, the measured supply temp never goes above 125*. I guess I expected it to be much higher since the CH Target Temp is 170*. Is this right or does it sound like there is a problem

There are no error codes or lockout. The only issue I see is that the domestic water temp sensor from the side arm water heater shows -22 but if I turn the hot water on in the house and the TT heats the water heater, the domestic water temp sensor shows 240 (which the manual shows as a short).

So, in short, things seem to work fine for the most part except in the morning, the house is at 65* when all the zones are set for 69*. Any insight would be greatly appreciated!

Thanks!

Brian

I've been trying to figure out why we aren't getting the same heat as before (a little chilly in the morning). By early day, things have caught up. Settings are all factory default except for the CH Target Temp is 170* instead of the 186* and the pressure is 12 PSI, which is recommended in the manual for residential.

In the morning, when several zones are requesting heat, the measured supply temp never goes above 125*. I guess I expected it to be much higher since the CH Target Temp is 170*. Is this right or does it sound like there is a problem

There are no error codes or lockout. The only issue I see is that the domestic water temp sensor from the side arm water heater shows -22 but if I turn the hot water on in the house and the TT heats the water heater, the domestic water temp sensor shows 240 (which the manual shows as a short).

So, in short, things seem to work fine for the most part except in the morning, the house is at 65* when all the zones are set for 69*. Any insight would be greatly appreciated!

Thanks!

Brian