SteveMitty79

Member

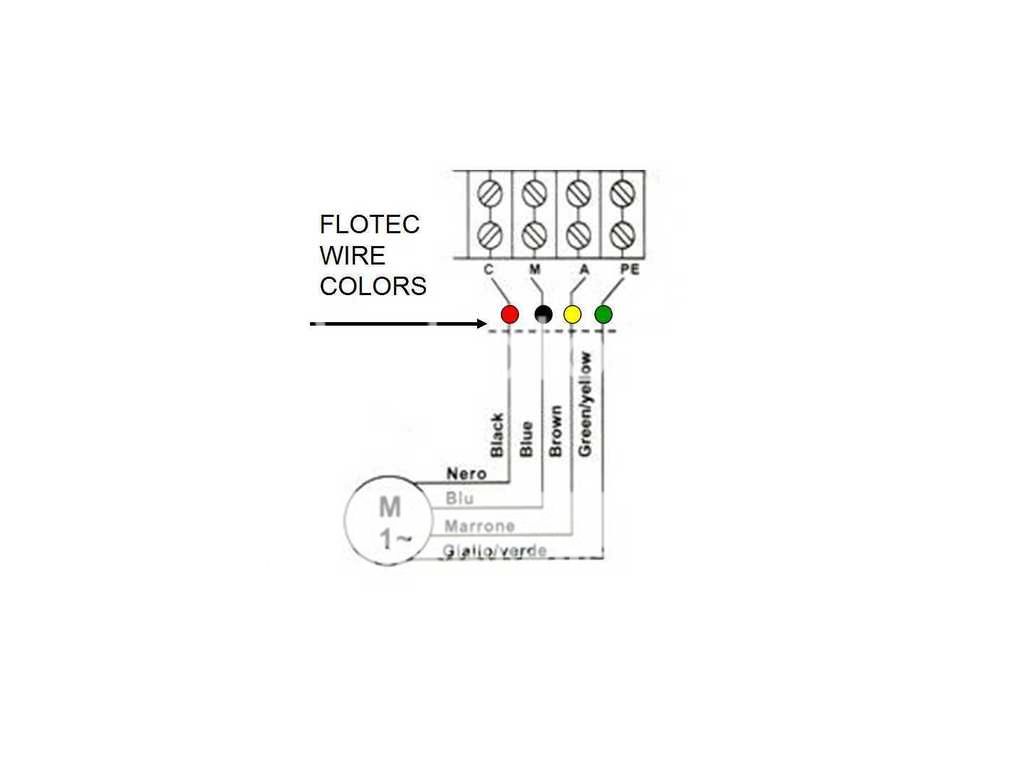

Because it is AC the P-P value for 120V is 120 X 1.414 or 169.68V p-p. Then it is good to add some overhead, so they use a 220V cap for a 120V Controller, And that is what you have.

You can measure the current of the start winding to see if it stuck in run.

And measure run current to see is it ever comes up to speed.

Ok on the capacitor values. Makes sense but you'd think they'd simply rate them accordingly.

Otherwise, measuring currents as quoted is to check the centrifugal switch to see if it's working properly?

Either way, I need another capacitor. What should I get?