tracyballard

Member

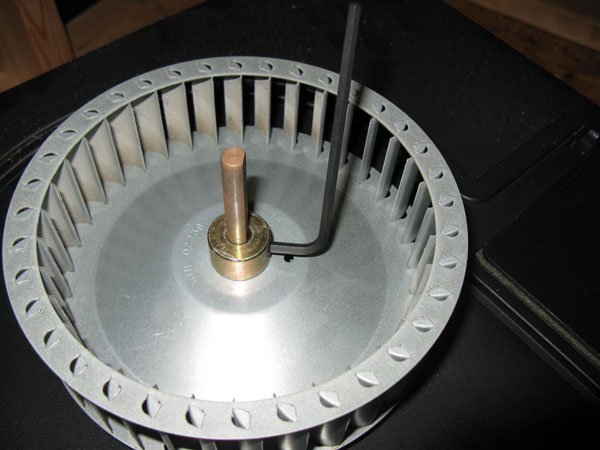

I've got to replace the draft inducer motor on my Carrier furnace, but I need to get the blower wheel off and the set screw will not budge. I've got the right allen wrench, even wrapped some tinfoil around it, but the screw will not turn. I've also been soaking it in gun oil and WD-40. I'm using a lot of force, and I haven't rounded it off yet, but this thing will not move whatsoever. If I can't get this off without messing up the blower wheel I'll have to wait til Monday for heat. Any ideas?