Hardly any organization ever admits they screwed up.

Yes I agree that with the CPSC, NFPA, and all the other NRTLs throughout America that should UL miss something that all these other testing labs and the Consumer Protect Protection Agency would just sit in silence and let the public be at risk.

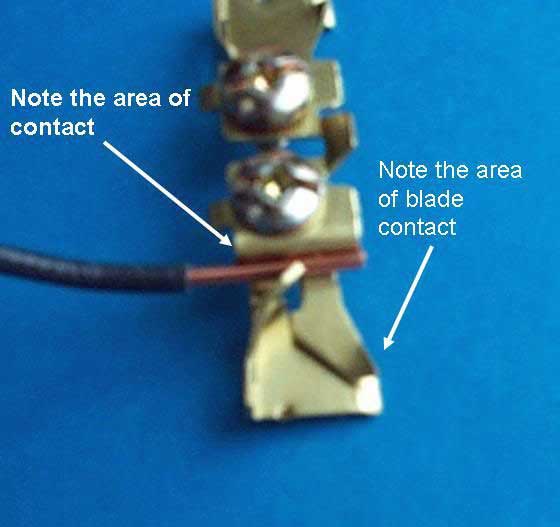

The plug on a cord has MUCH more surface area, and spot heating and resistance is less on heavy loads. The prongs on a back-stabbed device have much less surface area (but higher pressure). Given a choice, I'd prefer a device with a larger contact area, and that means a screw or a screw and clamp. Especially in a feed-through situation, I prefer a better connection than those small spring prongs.

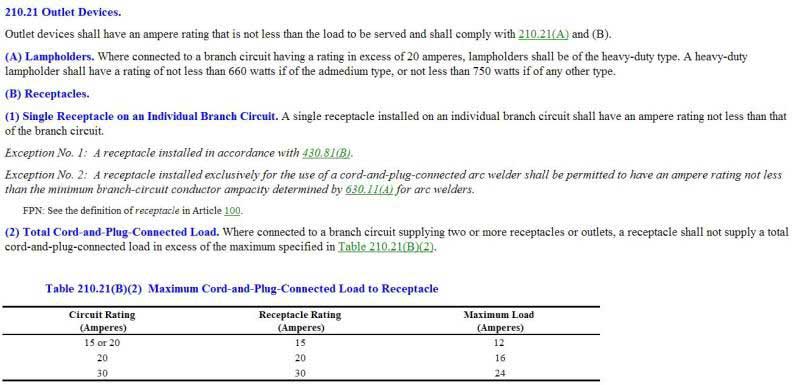

The area of contact of a stab-loc device is the area that is required for the 15 amp device to safely carry 12 amps which is the most that is allowed to be carried by any device installed on a 15 amp circuit installed in any manner in which it can be installed.

Should more amperage be allowed on this circuit there will be a failure somewhere on the device carrying the current which is a DIRECT VIOLATION OF BOTH THE NEC AND THE LISTING OF THE PRODUCT.

I had a friend call yesterday, who has three outlets in the master bedroom which do not work while the other three do. After talking to him, it appears that the only source of the problem must be where those three attach to the other three. AND, since the wiring is done with "back stabbing", the inference is that one of them must be faulty.

Every time this question is posted someone comes along with a friend that had one fail yesterday and cost millions of dollars in property damage and lost time. What no one has ever posted was what caused the failure. Without a doubt it is because one of two reasons, 1- improper installation, 2- overload. Which was the case with your friend?

You do not need Einstein to see that the tiny surface contact area of a stab in device is a problem waiting to happen. If pulled back hard when inserted and twisted a bit, it might be good forever. On high amp draws they likely arc until they melt together at which time they become "safer"

Take a look at 210.21(B)(2) of the NEC to see that a high amp draw is in violation.

Thatguy said a lot yesterday in two short paragraphs. Every post here has said pretty much the same thing. Thanks to the wisdom of crowds, I now vote against the jwelectric point of view. I might receive a failing mark if I were forced to take his course. It is true that ignorance "breeds" a fear.

A prime case of the blind leading the blind and the blind is blindly following;

My friend it is not the view of JW Electric but instead it is the view of

Underwriters Laboratories

Met Laboratories

Intertek Group

National Technical Systems, Inc.

Wyle Laboratories

Nemko

National Electrical Manufacturers Association

Just to mention a few and then we also have the Consumer Protect Protection Agency which orders a recall when a product is dangerous and causes all this damage that these uninformed people keep preaching about simply to make everyone think they know something that their jaw is proving they know nothing or little about.

So my friend it is not something that JW Electric is saying but the greatest electrical minds in the country and those minds who are charged with our safety are saying.

It is not me that those who think that the stab-loc is bad is arguing with but instead it is those who are charged with listing and labeling the product they are arguing with.

It is not me that they are turning up their noses at but those charged with mine and your safety they are looking down at.

Now the choice is yours. You can believe those who post of forums such as this one or you can believe those who spend millions of dollars each year testing the products we use everyday.

I would suggest that if you are going to take the word of the individuals who post on these forums that you take action to destroy all those fools who put their labels on the products saying they are safe to use.