Redwood

Master Plumber

600/100 = factor of safety = 6. But that ignores the factor of safety of the rating, which is probably 2, so that the actual FOS = 12. That big ol' lion in the house is now very small indeed. For a system used intermittently in a residence I see no problem.

http://www.osha.gov/dts/hib/hib_data/hib19880520.html

http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=INTERPRETATIONS&p_id=20202

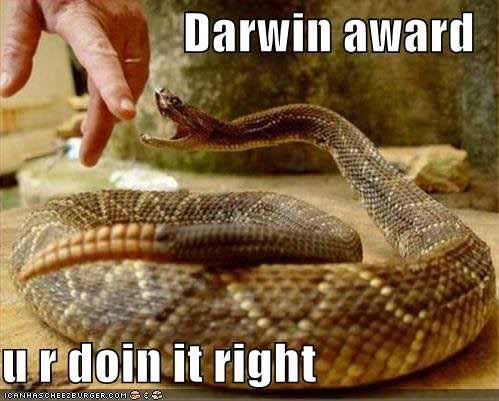

And you my friend are the recipient of todays award!

It always amazes me that someone when presented with overwhelming evidence that the position they have taken is wrong, and the opinion is shared by many others will continue to argue their point...

There must be a word for that...

Last edited by a moderator: