MacGyverMan

New Member

I am currently designing my well supplied plumbing system and am in search of information before moving forward.

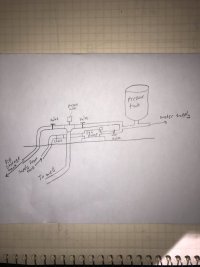

My system will temporarily supply some RVs, then a 4 bedroom house and some farm animals. So use will increase as time goes. I was planning to use a standard pressure tank system with 60-80 gal tank then to eventually augment with a surface storage tank for the purpose of water security as well as reducing well pump cycling. Much like this gentleman has setup.

This is what I am working with:

- 500ft well

- Static level 135ft

- Well supply 30gpm

- Well pump : Grundfos 10SQ15-330 (1.5hp)

- 1" ID, 200psi, poly drop pipe

- 1" ID poly from well head to pump house 15ft away

- 1" ID poly from pump house to RV/house site 250ft away (slight decline to level)

- I plan to set well pump at 260ft depth

- Generally, not super bitter winters but typically goes to 20 degrees for a week or so each winter

I calculate my THD to be 135ft + 140ft(60psi) = 275ft minimum to 260ft + 140ft = 400ft maximum if static level drops. This does not account for 250' run. At those depths I calculate well pump to supply 13gpm to 9.5gpm.

Questions:

- For plumbing my pressure tank system, surface pump and valves, should I run 1" PEX or 1" PVC? I desire pex for the freeze resistance and desire PVC for actual 1" ID and not further restricting my supply with pex .8" ID. (I do plan to use a 1 1/4" pressure tank).

- Im currently leaning toward PVC and using other measures to ensure pipes wont freeze, however pump house will not be heated.

- What pumps should I look at for my storage tank to pressure tank surface pump?

- How much PSI drop could I expect for that 250ft run after the pressure tank in 1" ID poly?

- I recently discovered CSVs. Other than adding cycling protection redundancy and the benefit of a constant PSI, I question if it further would benefit me due to our water habits. Mom and multiple kids stay at home during the day, thus hand washing and toilet flushing happen consistently throughout the day. I tend to think a pressure tank that can supply 2 toilet flushes and 4 hand washes before cycling the pump once would be better than a CSV that must turn on pump each time one of these are used apart from one another. (only pressure tank will be used for awhile before storage tank is installed).

- How would CSV work with the surface pump pumping from storage tank?

- When CSV limits well pump output, how will PSI increase in my plumbing and drop pipe?

- Is Grundfos 10SQ15-330 compatible with a CSV?

- Which CSV is recommended for my Grundfos pump and setup if they are compatible?

Appreciate any input and perspectives!

My system will temporarily supply some RVs, then a 4 bedroom house and some farm animals. So use will increase as time goes. I was planning to use a standard pressure tank system with 60-80 gal tank then to eventually augment with a surface storage tank for the purpose of water security as well as reducing well pump cycling. Much like this gentleman has setup.

This is what I am working with:

- 500ft well

- Static level 135ft

- Well supply 30gpm

- Well pump : Grundfos 10SQ15-330 (1.5hp)

- 1" ID, 200psi, poly drop pipe

- 1" ID poly from well head to pump house 15ft away

- 1" ID poly from pump house to RV/house site 250ft away (slight decline to level)

- I plan to set well pump at 260ft depth

- Generally, not super bitter winters but typically goes to 20 degrees for a week or so each winter

I calculate my THD to be 135ft + 140ft(60psi) = 275ft minimum to 260ft + 140ft = 400ft maximum if static level drops. This does not account for 250' run. At those depths I calculate well pump to supply 13gpm to 9.5gpm.

Questions:

- For plumbing my pressure tank system, surface pump and valves, should I run 1" PEX or 1" PVC? I desire pex for the freeze resistance and desire PVC for actual 1" ID and not further restricting my supply with pex .8" ID. (I do plan to use a 1 1/4" pressure tank).

- Im currently leaning toward PVC and using other measures to ensure pipes wont freeze, however pump house will not be heated.

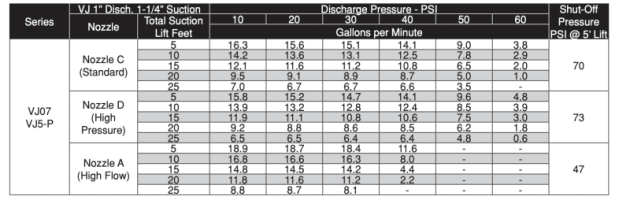

- What pumps should I look at for my storage tank to pressure tank surface pump?

- How much PSI drop could I expect for that 250ft run after the pressure tank in 1" ID poly?

- I recently discovered CSVs. Other than adding cycling protection redundancy and the benefit of a constant PSI, I question if it further would benefit me due to our water habits. Mom and multiple kids stay at home during the day, thus hand washing and toilet flushing happen consistently throughout the day. I tend to think a pressure tank that can supply 2 toilet flushes and 4 hand washes before cycling the pump once would be better than a CSV that must turn on pump each time one of these are used apart from one another. (only pressure tank will be used for awhile before storage tank is installed).

- How would CSV work with the surface pump pumping from storage tank?

- When CSV limits well pump output, how will PSI increase in my plumbing and drop pipe?

- Is Grundfos 10SQ15-330 compatible with a CSV?

- Which CSV is recommended for my Grundfos pump and setup if they are compatible?

Appreciate any input and perspectives!