reno3204

New Member

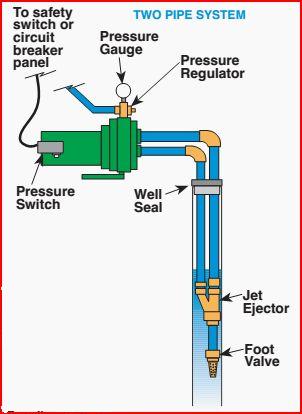

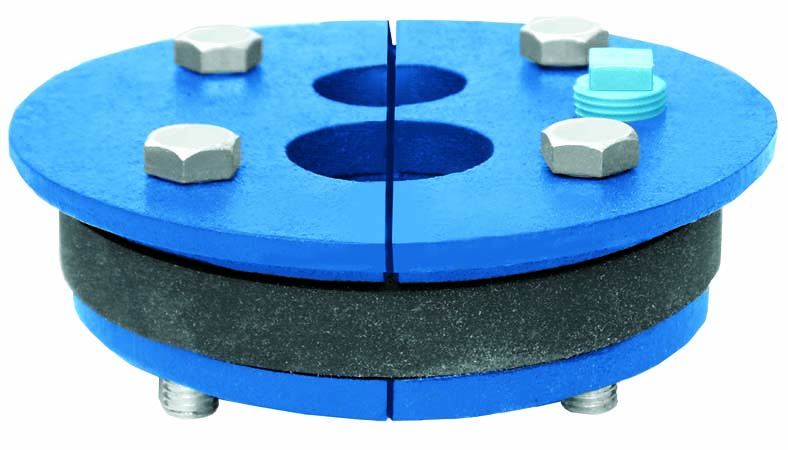

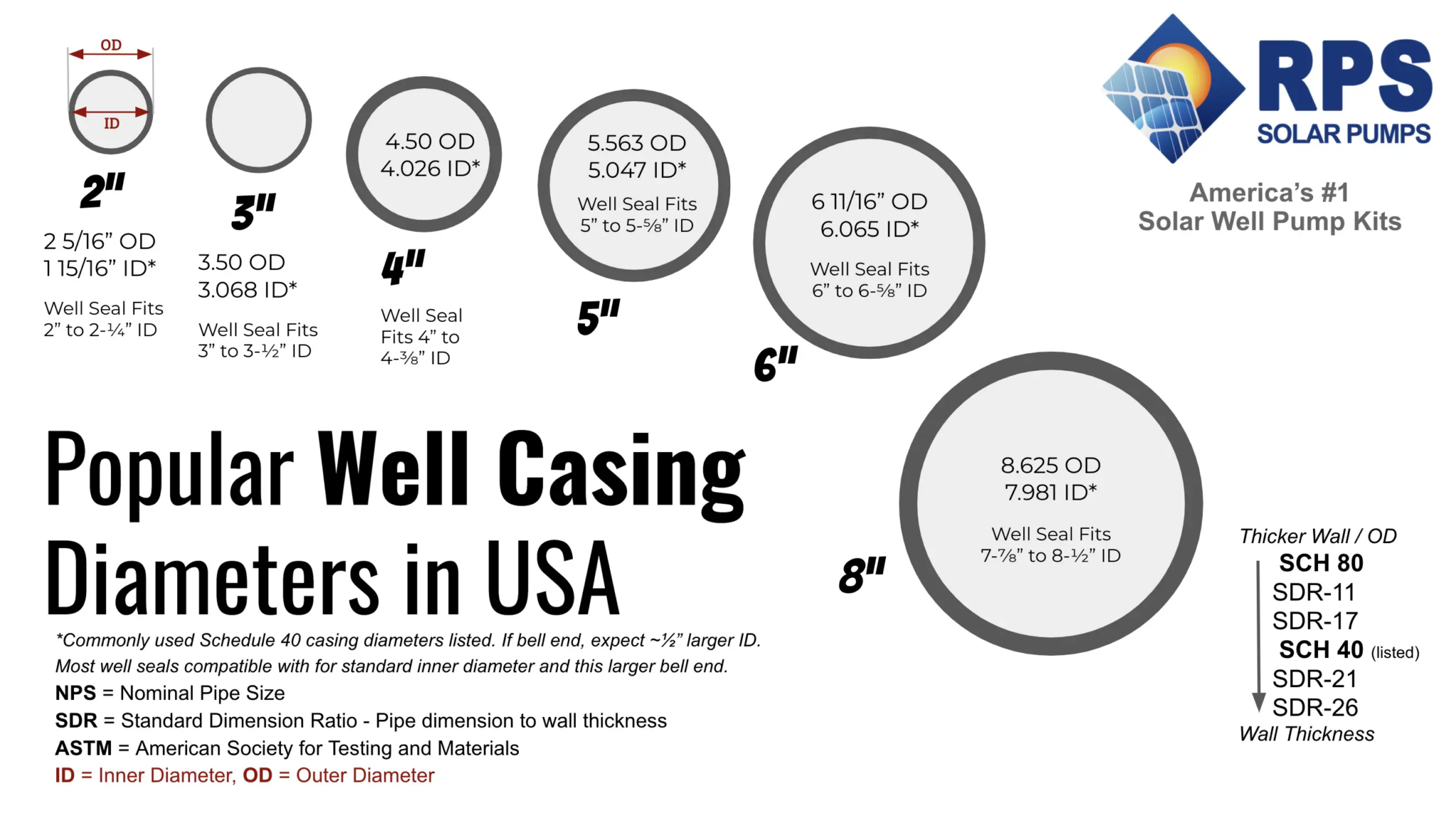

Renovating an old home with a jet pump well. The well has no seal on it. I have called two different well companies, sent them this picture and they say no problem we can take care of that and they give me a price. Then before they come and do the service they call back and say they don't usually service that kind of well and it will cost more or they can't get the part. Am I missing something? is there something difficult about putting a cap on this well.

Thanks

Thanks