Good morning, never had a well before but we are about to make that transition and this forum has been AMAZING for me to learn. I don't have my final well report yet it was just drilled last week but indications are it is low yield at about 1 GPM unfortunately. The well is about 500 ft, and 8" wide so there will be a decent storage in the bore (don't have the static level yet or depth the pump will be to know that exact #). We want to scale our system properly for 5 bedrooms and 4.5 baths, 3 levels including the basement. Allow for some lawn irrigation, and also I'm going to have a fairly high end shower with multiple body sprays on the top floor, the digital valve on my shower alone can support up to 17 GPM at 45psi (though normally the shower will probably use closer to 10). So I'm guessing peak would require 20 GPM.

So bottom line is I know I'm going to need a storage tank in the basement, probably in the 500-1000 gallon range. I think it is easy enough to make sure that gets supplied properly from the well since the well should in theory yield 1,400 gallons a day.

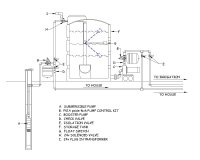

So based on what I'm reading here I'm going to ask for the the attached setup that valveman has posted several times. My question is on the booster after the storage tank. If I require say up to 20gpm at a constant pressure of 50 psi, I'm trying to calculate the size booster. Most supply lines to the fixtures will be 1/2" but my shower valve requires 3/4". I'm trying to get the builder to do PEX not CPVC I'm reading up on the friction loss between the two.

So if I'm following the calculators I can find online, if I stick with Grundfos I end up needing something like the CMBE 5-62 which is a pretty expensive/jacked up pump.

Am I on the right track with this? I want to make sure I get this right, even if oversizing a bit and I don't mind spending the extra $$?

So bottom line is I know I'm going to need a storage tank in the basement, probably in the 500-1000 gallon range. I think it is easy enough to make sure that gets supplied properly from the well since the well should in theory yield 1,400 gallons a day.

So based on what I'm reading here I'm going to ask for the the attached setup that valveman has posted several times. My question is on the booster after the storage tank. If I require say up to 20gpm at a constant pressure of 50 psi, I'm trying to calculate the size booster. Most supply lines to the fixtures will be 1/2" but my shower valve requires 3/4". I'm trying to get the builder to do PEX not CPVC I'm reading up on the friction loss between the two.

So if I'm following the calculators I can find online, if I stick with Grundfos I end up needing something like the CMBE 5-62 which is a pretty expensive/jacked up pump.

Am I on the right track with this? I want to make sure I get this right, even if oversizing a bit and I don't mind spending the extra $$?