Shaklee3

Member

Hi, I decided to make a new thread since these questions are unrelated to the tub drain slope.

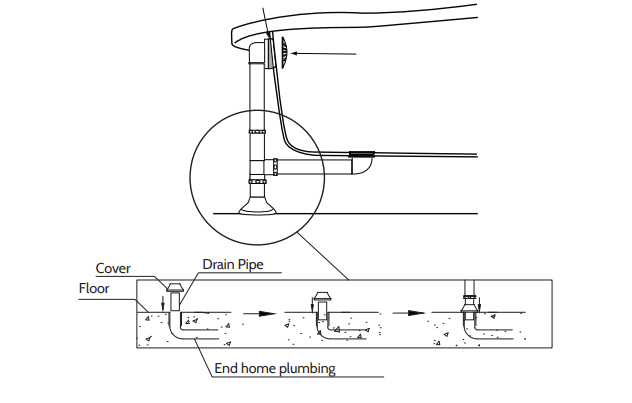

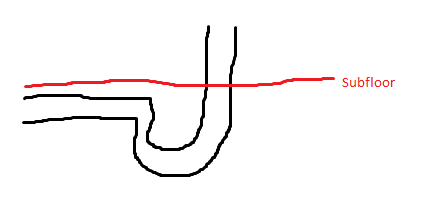

Question 1: I have a clawfoot tub with overflow drain that I'm installing where there used to be an alcove tub. A picture is attached of the current p-trap from the previous tub. The rough-in appears to be different than the alcove in that there's no threaded ABS drain piece, and instead they just show the drain going straight into the trap inlet. Does that mean my rough-in should just go completely vertically from the p-trap shown in my drawing straight through the subfloor with a 1.5" pipe, and just cut it to size when I get the tub parts? I don't see how it makes a seal with the floor drain in their instructions.

Question 2: My in-wall valve has a brass fitting with an O-ring that is tightened with the large nut in the picture shown. These will go down to the copper supply lines. Is the proper way to use the brass fitting as-is and use the o-ring for leak protection, and the NPT fitting use PTFE+dope to seal that, then solder the rest on? Is there a better way for this type of valve? Thanks!

Question 1: I have a clawfoot tub with overflow drain that I'm installing where there used to be an alcove tub. A picture is attached of the current p-trap from the previous tub. The rough-in appears to be different than the alcove in that there's no threaded ABS drain piece, and instead they just show the drain going straight into the trap inlet. Does that mean my rough-in should just go completely vertically from the p-trap shown in my drawing straight through the subfloor with a 1.5" pipe, and just cut it to size when I get the tub parts? I don't see how it makes a seal with the floor drain in their instructions.

Question 2: My in-wall valve has a brass fitting with an O-ring that is tightened with the large nut in the picture shown. These will go down to the copper supply lines. Is the proper way to use the brass fitting as-is and use the o-ring for leak protection, and the NPT fitting use PTFE+dope to seal that, then solder the rest on? Is there a better way for this type of valve? Thanks!

Last edited: