Shibby021

New Member

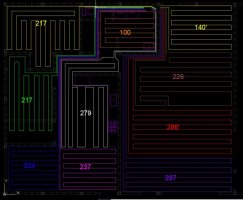

Hi, I live in north central MN, it can get down and stay in the negative temps for a month or 2, and I have some questions about doing my in floor heating setup before pouring concrete this friday.

most of the lines are 12" spaced from each other.

I am wondering if pex can cross over each other?

How close apart from each other should they be on the supply/return alley?

How far should the exterior perimeter pex be from the slab exterior perimeter?

I have attached 2 images, both are same design, just different background color. Not sure which appears better for each person viewing.

217 master bedroom

217 green guest room/office

224, 237, and 279 are one big open space with 279 being the kitchen

100 is utility/bathroom where the boiler/manifold will be mounted.

140,226,286, and 297 are shop area. 140 is where work bench will be, 297 is what I call a apron, where trench drain will be and where I melt the snow off snowmobiles and equipment before completely bringing them further inside the shop.

The garage door is right below 297 not on the right. the area on the right will be another insulated building with its own radiant slab heating.

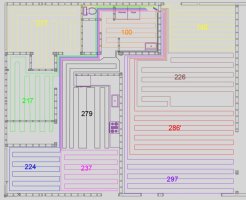

most of the lines are 12" spaced from each other.

I am wondering if pex can cross over each other?

How close apart from each other should they be on the supply/return alley?

How far should the exterior perimeter pex be from the slab exterior perimeter?

I have attached 2 images, both are same design, just different background color. Not sure which appears better for each person viewing.

217 master bedroom

217 green guest room/office

224, 237, and 279 are one big open space with 279 being the kitchen

100 is utility/bathroom where the boiler/manifold will be mounted.

140,226,286, and 297 are shop area. 140 is where work bench will be, 297 is what I call a apron, where trench drain will be and where I melt the snow off snowmobiles and equipment before completely bringing them further inside the shop.

The garage door is right below 297 not on the right. the area on the right will be another insulated building with its own radiant slab heating.

Attachments

Attachments

Last edited: