DECJ

New Member

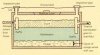

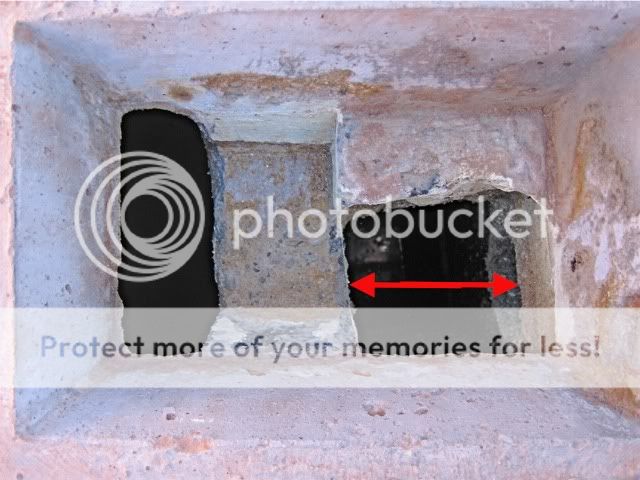

After a lot of frustrating trouble-shooting, we finally discovered that we had a major toilet paper clog in the first chamber of our 1000 gallon concrete septic tank. We just had the tank pumped out this morning and after talking with the pump-out guy and then calling the septic tank manufacturer, they both recommended that I install a sanitary tee on the otherwise straight input pipe that enters our septic tank. And here is a pic of the current input line:

I now have the 4" sanitary tee, but I have a question before I proceed. I know that I will be gluing on a straight extension pipe to the bottom port to extend down into the middle water layer in the tank, but what do I do with the unused upper port of the tee? Should I cap that off, or should I leave it open? Also, if I cap it off, does the fact that the end of the input line will now be below the surface of the tank contents cause any undue back pressure as sewage & waste water leaves our house and dumps into the tank (as compared to the straight pipe that is currently above the tank level now)?

I would sure appreciate any help or advice on this.

Thanks,

Don

I now have the 4" sanitary tee, but I have a question before I proceed. I know that I will be gluing on a straight extension pipe to the bottom port to extend down into the middle water layer in the tank, but what do I do with the unused upper port of the tee? Should I cap that off, or should I leave it open? Also, if I cap it off, does the fact that the end of the input line will now be below the surface of the tank contents cause any undue back pressure as sewage & waste water leaves our house and dumps into the tank (as compared to the straight pipe that is currently above the tank level now)?

I would sure appreciate any help or advice on this.

Thanks,

Don

Last edited by a moderator: