Looking at some of those mini split systems, knowing that I won't be doing any of the installation, I can't see getting out of a full-home system (outdoor unit, 4 indoor units, ducting, and associated installation) for less than $12K, and probably more than that. For some context on the cost of professional trade work in Seattle, the going rate for the installation of a single electrical outlet is about $500 once permits and taxes are factored in. So, $12K (and likely more) for a brand new heating system, and I still need some type of DHW system to go inside a tiny utility room (55 tank system will not fit), and I'm in it for another $3K-$5K on top of the >$12K.

Given an array of solutions that are all flawed in some significant way, I tend to agree with Wayne - that adding thermal mass to the system and using a combi for DHW and space heat is the best approach all things considered. Regardless of heating system, I still need a source of DHW, and I already have the fin tube baseboards and plumbing in place, so I can't see anything other than a combi being able to address the issue given utility room space and cost constraints. Which is funny in a way, I guess, as I started this whole thread concerned about the $10K+ costs associated with going with a combi install.

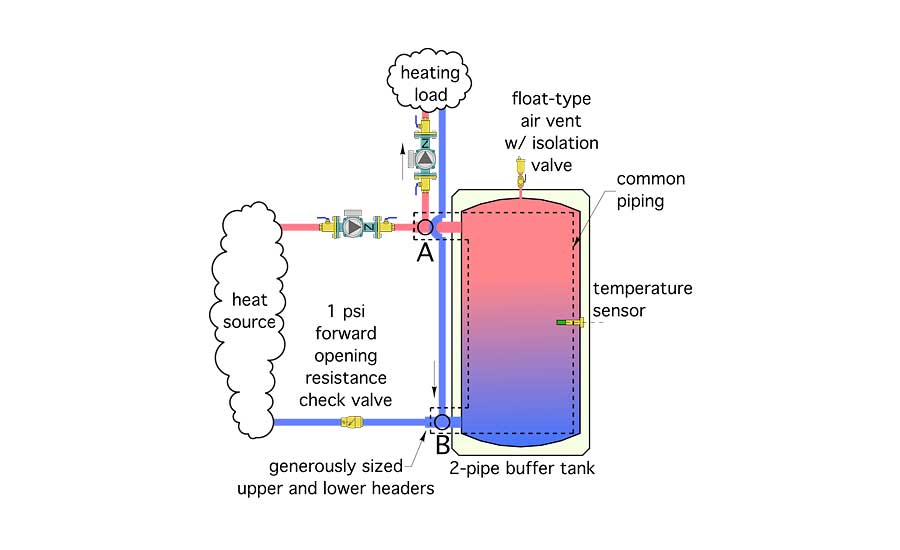

Getting into the buffer tank approach opens its own can of worms - 4 pipe vs 2 pipe? Like pretty much everything, ask 10 people, get 10 different opinions. I can tell you this, paying $1,000 for a specifically-designed small (~20 gal), 4-pipe buffer tank is insanity. So, going with a using a small point of use tank heater like Wayne suggests seems like the way to go, and those all tend to have only 2 connections so looks like it'll be a 2 pipe approach for the buffer thank. Then, there's the issue of how exactly you plumb the 2 pipe buffer: 1) on the primary loop and before the heating load? 2) on the primary loop and after the load? 3) in series or in parallel on either the supply or return side? 4) and then do you pipe the input at the top and output out the bottom or vice versa? In my research, I've found pros far knowledgeable than me arguing passionately for every single one of those permutations. I found this thread

https://forum.heatinghelp.com/discussion/104424/buffer-tank-question from back in 2007 pretty interesting as it contains a post (5th in the thread, from user MikeL_2) who apparently tried multiple buffer tank piping approaches collecting data on cycle length and determined that on the supply side (after boiler, before load), in series, and with the input at the top and output at the bottom, to be the most efficient approach.

John Siegenthaler appears to be someone whose opinions carry a lot of weight related to HVAC engineering, and on this page:

https://www.pmmag.com/articles/100544-the-finer-points-of-applying-a-2-pipe-buffer-tank he weighs in on the merits for a 2-pipe approach in such a way that the buffer tank itself makes up the bulk of the primary loop with the supply and return T's for the secondary loop closely adjacent to the input/output of the 2 pipe buffer:

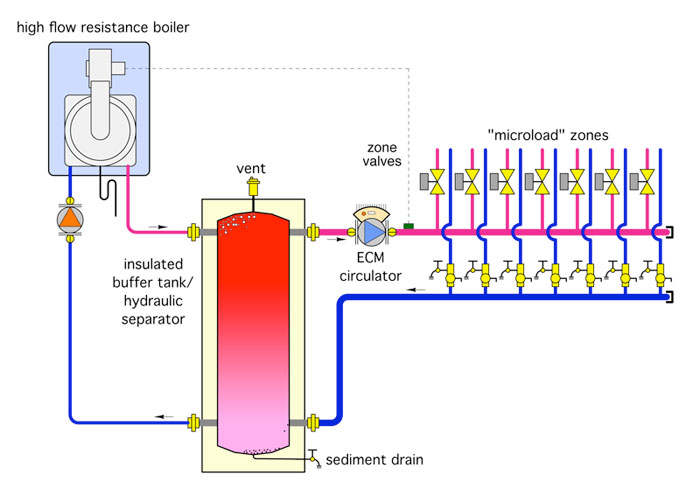

He also appears to suggest using a specifically designed buffer tank that will suppor the installation of air escape valve at the top - not something that a repurposed point of use tank will support, but I imagine there must be other ways to release air trapped in the buffer tank during filling. I have also read that "supply houses" carry tank "carcasses" that haven't yet been outfitted with the heating element and other components for less than an actual functioning tank, so I might look into that. As a place to start, the Rheem 10 gallon point of use heaters like this one:

seem promising, so I will start looking there.