Derek R

New Member

So my wife and I just bought a new (to use, built in 92) home to raise our 18mo twin boys in. We were both raised on city water, but our new residence has private well, private septic. I'm completely lost on both topics, but, just focusing on the private well now.

Side note: home was empty for 6 months before we purchased.

This is the layout of our system:

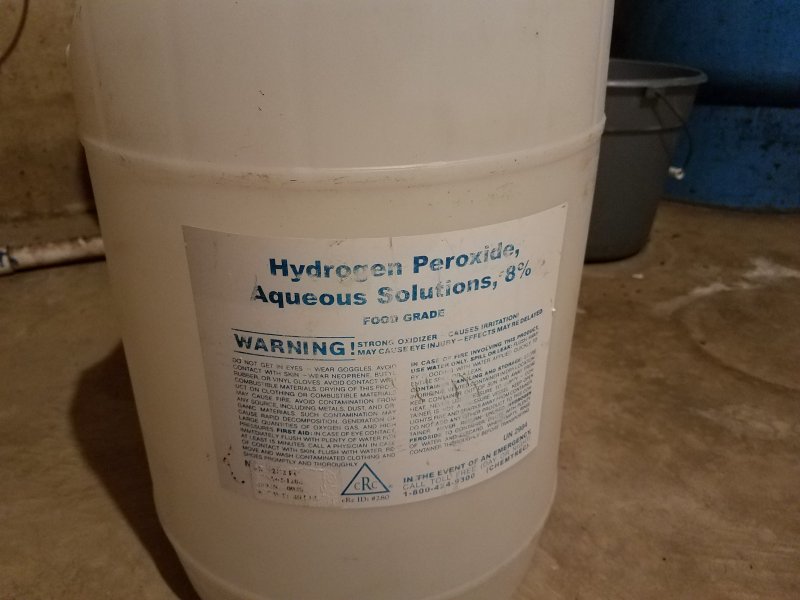

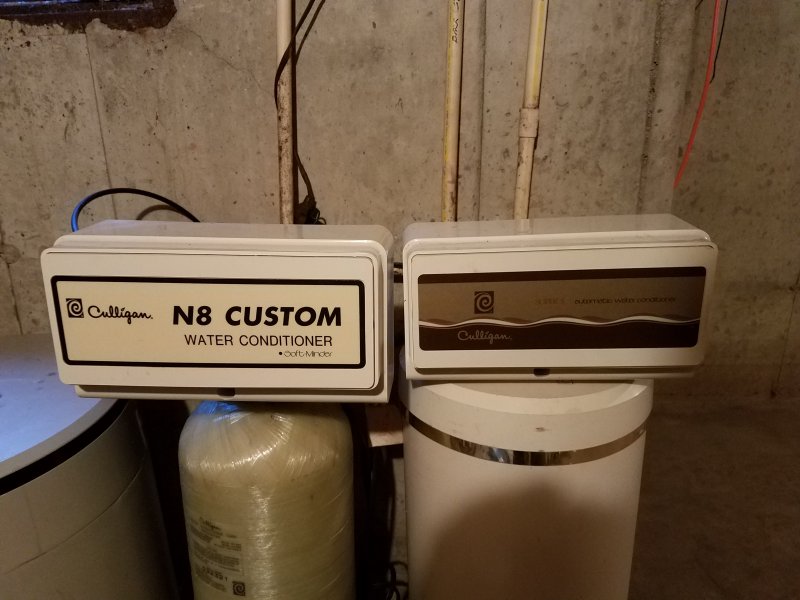

Well pump > Stenner 85mhp40 chemical pump (they left a empty bottle of 8% food grade hydrogen peroxcide) > Culligan Super S automatic conditioner > Culligan N8 custom water conditioner > supply line for house.

There is also a additional 3 stage DuPont water filter system at the kitchen sink that preludes a drinking water tap.

1. What is the purpose of the Stenner Chem pump and the H2O2?

2. The only thing I know about the softening system is that salt goes in the brine tank. The question about that is a lot of people have told me that there brine tank has very little water

in it, where my float is set to hold about 3/4 of a tank.

in it, where my float is set to hold about 3/4 of a tank.

I have yet to put salt in the system bc I want to make sure the water level is accurate.

Water from the faucet does have a rotten egg smell to it.

Can you help point me in the right direction?

Side note: home was empty for 6 months before we purchased.

This is the layout of our system:

Well pump > Stenner 85mhp40 chemical pump (they left a empty bottle of 8% food grade hydrogen peroxcide) > Culligan Super S automatic conditioner > Culligan N8 custom water conditioner > supply line for house.

There is also a additional 3 stage DuPont water filter system at the kitchen sink that preludes a drinking water tap.

1. What is the purpose of the Stenner Chem pump and the H2O2?

2. The only thing I know about the softening system is that salt goes in the brine tank. The question about that is a lot of people have told me that there brine tank has very little water

I have yet to put salt in the system bc I want to make sure the water level is accurate.

Water from the faucet does have a rotten egg smell to it.

Can you help point me in the right direction?

Last edited: