Sorry, I am not understanding your question. No disrespect meant at all, just 30+ years of field/manufacturing experience. After seeing countless failures caused by thermal expansion, and considering the extremely low cost of a quality check valve/thermal expansion tank when a system is located close to a water heater, I tend to err on the side of installing a$10 check valve and a $45 thermal expansion tank rather than hoping that 95% of the time that no problem will occur... this still leave 5% of the time that a major problem

may occur. I am not rich by any means, but <$100 is cheap insurance compared to spending hours if not days of labor clearing line of resin or other medias should a problem occur. A recent problem that occurred cost me over 150 hours of high cost labor due to a $5 error, needless to say, as a manufacturer I have a very different perspective. When someone sends you a bill for 100K, your mindset changes to "the little things matter". Especially when we are talking about <$100 of properly installed low cost/maintenance components could have eliminated the problem in the first place. Regardless, a thermal expansion tank is a cheap item that can prevent a lot of plumbing problems including ruptured hoses, flex lines etc. and not just at the filtration equipment, laundry, dishwasher etc. Thermal expansion is nothing new or exciting, it has been understood for decades at minimum. When water heats, it expand, that hot water has to go somewhere. It only has 1 direction to go, back to the city. If your water softener/filter is between the city and the water heater (which it is 99.99% of the time) that is where it will go. I design and sell units that are rated for up to 180F, but these are very specialized pieces of equipment utilizing stainless steel tanks and brass control valves with specialized rubber materials that can withstand these higher temperatures... Even lower temperature <150 degrees are still limited to specialized designs including vinyl ester tanks, brass valves etc. and take careful consideration in their design to ensure reasonable service intervals. If we were to use your numbers, assuming 3/4" type L, we can simply estimate that 10' would hold .25 gallons of water... and a simple plastic filter is probably far more fragile than a fiberglass wound mineral tank that is regularly tested by ASME to 600+ PSI.

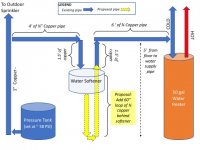

https://www.pentair.com/en/products/residential-water-treatment/professional-series/asme-tanks.html. When you install equipment near a water heater, install a check valve and thermal expansion tank to prevent problems. If you are on a pumped pressure supply system from your municipality (not a water tower) install a pressure regulator and maintain it. If you have stainless braided flex lines, replace them every 5 years. Some companies offer a 10 year warranty, but since most of these companies don't last 10 years, I am not sure what that is worth. I spend many hours a week on the phone dealing with problems that could have easily been avoided with a little extra effort on the front end rather than chasing problems that have been seen thousands of times and are nothing new, the old saying still applies, a Penny saved can cost you thousands.. I may have changed the old saying slightly but I am sure you get the point.