doug jabor

New Member

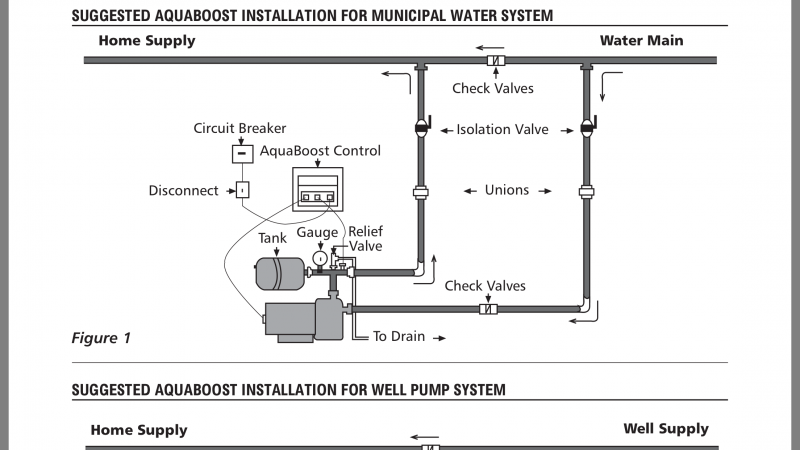

Hi all. I have a question about a symptom i am seeing on an aqauboost II controller and water booster pump system that is for the most part configured exactly like you see in the attached drawing, with the exception that there is no check valve on the suction side of the pump.... This system is 8 years old, and I never remember seeing this problem before, but here is what happened.

The first problem that is new was that the pump was never shutting down under no load conditions. Xylem techs told me to check the pressure in the V6P diaphragm tank as a starting point 9 see diagram). I replaced it instead and found that after I took the old tank off, and tested the pressure, it was at zero. The new one ( and the old one) comes pre charged at 38 psi. I run the system at 60 psi.

Now what is happening is that under no load conditions, the pump runs to like 62 , comes down to 60 and the pump shuts off... for about 4 seconds, then I see the pressure on the discharge drop to about 58, the pump kicks back on and goes to 60, then 62, then comes back down to 60 and shuts off... then repeats this cycle. When I close the valve to the suction side under no load , the pump stops and stays there. When i shut the valve on the discharge side, the pump just targets around 60 and does no shut off.

Is the problem that there is no check valve on the suction, so after the pump reaches 60 psi and shuts off., some of the 60 psi discharge pressure sneaks past the impeller to the suction side, and when it hits 58 psi, the pump kicks back on and so on?? It can't be a leaking bypass check ( see diagram) correct? otherwise, when I shut the suction side valve off, the pump would keep running.

Does this make sense?? IF so, can you recommend the correct type of check valve to install on the suction side of this system so the pump,p actually stays off under no load conditions??

Thank you!

The first problem that is new was that the pump was never shutting down under no load conditions. Xylem techs told me to check the pressure in the V6P diaphragm tank as a starting point 9 see diagram). I replaced it instead and found that after I took the old tank off, and tested the pressure, it was at zero. The new one ( and the old one) comes pre charged at 38 psi. I run the system at 60 psi.

Now what is happening is that under no load conditions, the pump runs to like 62 , comes down to 60 and the pump shuts off... for about 4 seconds, then I see the pressure on the discharge drop to about 58, the pump kicks back on and goes to 60, then 62, then comes back down to 60 and shuts off... then repeats this cycle. When I close the valve to the suction side under no load , the pump stops and stays there. When i shut the valve on the discharge side, the pump just targets around 60 and does no shut off.

Is the problem that there is no check valve on the suction, so after the pump reaches 60 psi and shuts off., some of the 60 psi discharge pressure sneaks past the impeller to the suction side, and when it hits 58 psi, the pump kicks back on and so on?? It can't be a leaking bypass check ( see diagram) correct? otherwise, when I shut the suction side valve off, the pump would keep running.

Does this make sense?? IF so, can you recommend the correct type of check valve to install on the suction side of this system so the pump,p actually stays off under no load conditions??

Thank you!