Dilapidatedwhale

New Member

Hello all,

Great forum (Thanks Terry!). I have learned a great deal from this forum while pouring through plumbing code for most of last winter, and I am currently tackling a plumbing job in my first house.

I am including background and other information in case it helps,

Background: House was plumbled in ~1956. Single bathroom that sits over a cellar (tornado shelter?) that is approx 5' x 8'. All plumbing for the house is in this pit (Edge of kitchen sits over it, 3/4 of bathroom sits over it, trap door in bathroom). House will have single kitchen sink, single tub, single vanity sink in bathroom, and single toilet when this project is finished. Pit is very cramped. Main power feed also arrives at edge of this pit and goes up into bathroom wall where breaker panel lives (being replaced), but breaker panel is on other side of wall, so no concerns about breaker panel being accessible from wet room.

Relevant history (I think): The original cast system used 3x 4" sanitary tees between toilet and the horizontal pipe that exits the cellar wall and heads straight out to septic tank. There was a single vent; 2" galvanized that connected through some rubber hose due to space constraints; house always had problems with clogs and traps being siphoned. It was gross and after seeing two sanitary tees being used to transition from vertical drop to horizontal, realizing that 2 sections of pipe were corroded loose, and parts of the sanitary tees had more than 1.5" deep of sludge, I decided to rip everything out. I poked 3" PVC thru the cellar wall, married it to the old cast in crawl space with a fernco hub to PVC metal banded union, and began figuring out how to make it all work.

Finally, pictures + questions below pics in bold:

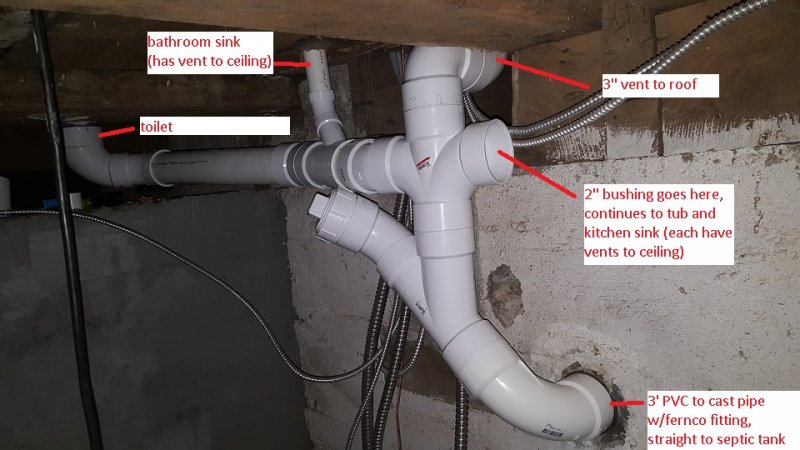

See picture. This is after reading this forum for many hours, and this is after many iterations.

Notes:

--Vent has been increased to 3" all the way thru roof.

--Every fixture has its own vent going up to ceiling and meeting main 3" vent thru appropriate fittings with appropriate slope, and within the thermal envelope of the house. Vent size is equal to drain size in all cases, sizes are as follows: Kitchen sink 2", tub 2", bathroom sink 1.5". Each fixture has a sanitary tee, the top of which connects to vent up to ceiling and bottom goes thru floor to cellar.

--Toilet has 4" piece of pipe dropping down from flange to 4"-3" closet elbow, length of 4" pipe allows for standard 1/4" per ft slope (I did this because the bathroom sink drops into the toilet stretch of pipe, I believe it is possible to use greater slope coming from toilet to wye or san-T if it is alone)

Side view (can see everything that is dry fitted right now):

Front view (looking straight at cellar wall where septic pipe exits, pic is slightly crooked sorry):

Apologies for the wire mess in the picture, house wiring is on hold until drains properly configured.

QUESTION #1:

-Do you think the inspector will be very unhappy about this horizontal jog in the vent, just above the sanitary tee? The vent at the top of the stack has two elbows allowing it to jog "back" into the hole you see in the concrete - This is unavoidable as the concrete wall and the wall above it is load bearing and could not be relocated; The only other wall that sits over this pit is the kitchen wall which is full of wiring and other things that prevent a 3" vent from running down and would also be 6 feet from where the main drain exits the wall and would *also* mean that most of the cellar would be pipes and there would be no room for water heater, softener, iron filter, bladder tank. The OLD vent also did this but it made a 20" sideways jog of 2" pipe instead of this ~6" sideways jog of 3" pipe that I have here. I can not come up with any other solution short of having an exposed pipe running though my bathroom. The bathroom is very small (5 x 9) and there is just no room for this.

CONCERN #2:

-Note the 3" double sanitary tee (sanitary cross?).

I am fully aware of the serious concern regarding modern toilets connected back to back through a sanitary tee, but what if it is only a single toilet (+ sink) on one side, and a tub + kitchen sink on the other?

One side is connected to the toilet (as you should be able to see from the picture) and also has the bathroom sink dropping into it from above. The other (right with respect to picture) side of this sanitary tee is intended to get a 3" to 2" bushing, and the 2" line extending from that will continue in that direction and pass under (and connect to) the tub and the kitchen sink (which both have their own vents to ceiling). Even if my inspector would pass this, would it be better to instead use a single 3" sanitary tee that has a 2" side inlet on it and run the tub and kitchen sink to the side inlet? ***disclaimer***: I realize that I could put a combo wye coming out of the wall, long sweep upward and then put the cleanout coming horizontally out of wye, which would solve vertical clearance issue, but the problem with this is that it would stick out another ~4" and this cellar is so narrow in this spot that it would make it nearly impossible to not undersize the water heater for clearance reasons. I really want to keep this config if possible, I think it is much better than original plumbing but I also don't want nightmares later... This is why I am asking about sanitary tee with side inlet vs sanitary cross.

Please also call out anything else you see as a problem. Thanks in advance for any and all suggesstions. I have learned more than I ever wanted to know about plumbing and I'm sure I will learn much more before this is done. I wish I could afford to pay someone to do this stuff but it's just not on the menu!!!

Edit: I should also add: The toilet is an American Standard "Cadet 3" dual flush 1.0/1.6pgm model.

Great forum (Thanks Terry!). I have learned a great deal from this forum while pouring through plumbing code for most of last winter, and I am currently tackling a plumbing job in my first house.

I am including background and other information in case it helps,

Background: House was plumbled in ~1956. Single bathroom that sits over a cellar (tornado shelter?) that is approx 5' x 8'. All plumbing for the house is in this pit (Edge of kitchen sits over it, 3/4 of bathroom sits over it, trap door in bathroom). House will have single kitchen sink, single tub, single vanity sink in bathroom, and single toilet when this project is finished. Pit is very cramped. Main power feed also arrives at edge of this pit and goes up into bathroom wall where breaker panel lives (being replaced), but breaker panel is on other side of wall, so no concerns about breaker panel being accessible from wet room.

Relevant history (I think): The original cast system used 3x 4" sanitary tees between toilet and the horizontal pipe that exits the cellar wall and heads straight out to septic tank. There was a single vent; 2" galvanized that connected through some rubber hose due to space constraints; house always had problems with clogs and traps being siphoned. It was gross and after seeing two sanitary tees being used to transition from vertical drop to horizontal, realizing that 2 sections of pipe were corroded loose, and parts of the sanitary tees had more than 1.5" deep of sludge, I decided to rip everything out. I poked 3" PVC thru the cellar wall, married it to the old cast in crawl space with a fernco hub to PVC metal banded union, and began figuring out how to make it all work.

Finally, pictures + questions below pics in bold:

See picture. This is after reading this forum for many hours, and this is after many iterations.

Notes:

--Vent has been increased to 3" all the way thru roof.

--Every fixture has its own vent going up to ceiling and meeting main 3" vent thru appropriate fittings with appropriate slope, and within the thermal envelope of the house. Vent size is equal to drain size in all cases, sizes are as follows: Kitchen sink 2", tub 2", bathroom sink 1.5". Each fixture has a sanitary tee, the top of which connects to vent up to ceiling and bottom goes thru floor to cellar.

--Toilet has 4" piece of pipe dropping down from flange to 4"-3" closet elbow, length of 4" pipe allows for standard 1/4" per ft slope (I did this because the bathroom sink drops into the toilet stretch of pipe, I believe it is possible to use greater slope coming from toilet to wye or san-T if it is alone)

Side view (can see everything that is dry fitted right now):

Front view (looking straight at cellar wall where septic pipe exits, pic is slightly crooked sorry):

Apologies for the wire mess in the picture, house wiring is on hold until drains properly configured.

QUESTION #1:

-Do you think the inspector will be very unhappy about this horizontal jog in the vent, just above the sanitary tee? The vent at the top of the stack has two elbows allowing it to jog "back" into the hole you see in the concrete - This is unavoidable as the concrete wall and the wall above it is load bearing and could not be relocated; The only other wall that sits over this pit is the kitchen wall which is full of wiring and other things that prevent a 3" vent from running down and would also be 6 feet from where the main drain exits the wall and would *also* mean that most of the cellar would be pipes and there would be no room for water heater, softener, iron filter, bladder tank. The OLD vent also did this but it made a 20" sideways jog of 2" pipe instead of this ~6" sideways jog of 3" pipe that I have here. I can not come up with any other solution short of having an exposed pipe running though my bathroom. The bathroom is very small (5 x 9) and there is just no room for this.

CONCERN #2:

-Note the 3" double sanitary tee (sanitary cross?).

I am fully aware of the serious concern regarding modern toilets connected back to back through a sanitary tee, but what if it is only a single toilet (+ sink) on one side, and a tub + kitchen sink on the other?

One side is connected to the toilet (as you should be able to see from the picture) and also has the bathroom sink dropping into it from above. The other (right with respect to picture) side of this sanitary tee is intended to get a 3" to 2" bushing, and the 2" line extending from that will continue in that direction and pass under (and connect to) the tub and the kitchen sink (which both have their own vents to ceiling). Even if my inspector would pass this, would it be better to instead use a single 3" sanitary tee that has a 2" side inlet on it and run the tub and kitchen sink to the side inlet? ***disclaimer***: I realize that I could put a combo wye coming out of the wall, long sweep upward and then put the cleanout coming horizontally out of wye, which would solve vertical clearance issue, but the problem with this is that it would stick out another ~4" and this cellar is so narrow in this spot that it would make it nearly impossible to not undersize the water heater for clearance reasons. I really want to keep this config if possible, I think it is much better than original plumbing but I also don't want nightmares later... This is why I am asking about sanitary tee with side inlet vs sanitary cross.

Please also call out anything else you see as a problem. Thanks in advance for any and all suggesstions. I have learned more than I ever wanted to know about plumbing and I'm sure I will learn much more before this is done. I wish I could afford to pay someone to do this stuff but it's just not on the menu!!!

Edit: I should also add: The toilet is an American Standard "Cadet 3" dual flush 1.0/1.6pgm model.

Last edited: