gosko

New Member

Hi, I just bought my first home and am doing a number of updates. It is a single-level place with 3 bedrooms and 2 bathrooms, about 1500 sq feet with easy access from above and below via attic and crawl space.

I had a new tankless hot water system installed (a Bosch T9800, 200k BTU natural gas), and once it's fired up it does a good job of pumping out tons of hot water.

But the startup time is really disappointing - starting from a cold system and cold pipes it takes about 1 min 40 seconds to start putting out hot water from a single bathroom faucet maybe 20 feet away.

If I come back 20 minutes later it starts warm and gets hot within about 20 seconds which is fine, but if I come back an hour or two later it's ice cold again and takes 1 min 40 seconds to get hot.

What's a reasonable time to expect hot water from a modern tankless system, assuming it's installed and working well? (good gas pressure, typical piping) The house and plumbing is 30 years old, and generally well-built and cared for.

My impression is that this gas-fired tankless system is great at putting out tons of hot water when needed but takes a long time to start up and shut down, so it doesn't work very well with small volumes and random usage patterns. (e.g. washing hands for 10 seconds, or getting turned on/off frequently while rinsing dishes)

Does it sound like this system is working as designed? If so, any suggestions for what I could do to get quicker access to small volumes of hot water at sinks throughout the house?

One idea I had would be to install an electric point-of-use system with a small tank (maybe 2-4 gallons) somewhere close to all the faucets so I would always have quick access to hot water, then connect that to the big gas-fired tankless system so it's able to keep up with higher volumes when needed. Does that make sense?

There are 4 sinks where I would like to have reasonably quick access to hot water and I am hoping all of them could be fed by a single point-of-use system installed in the crawl space, rather than installing a separate one for each sink.

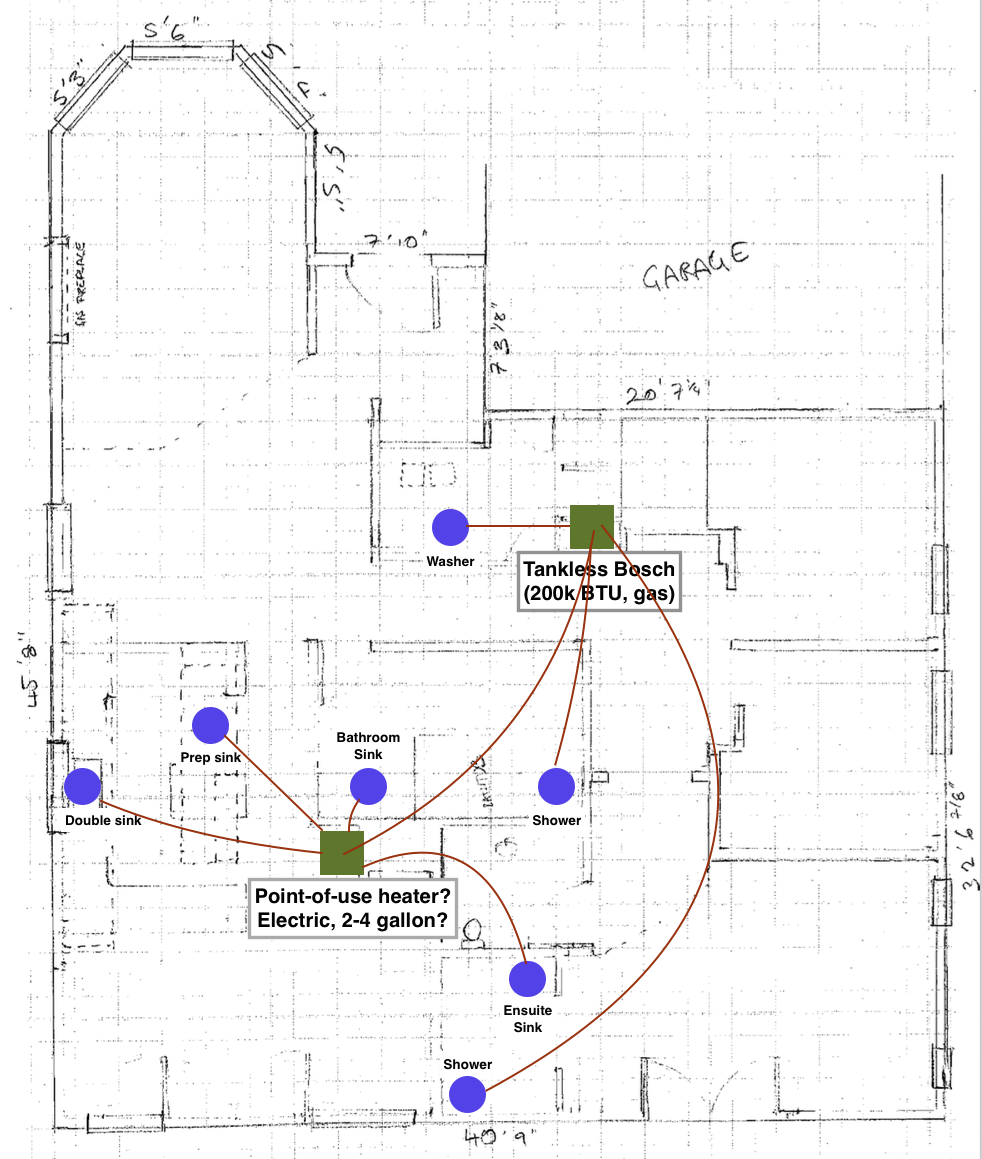

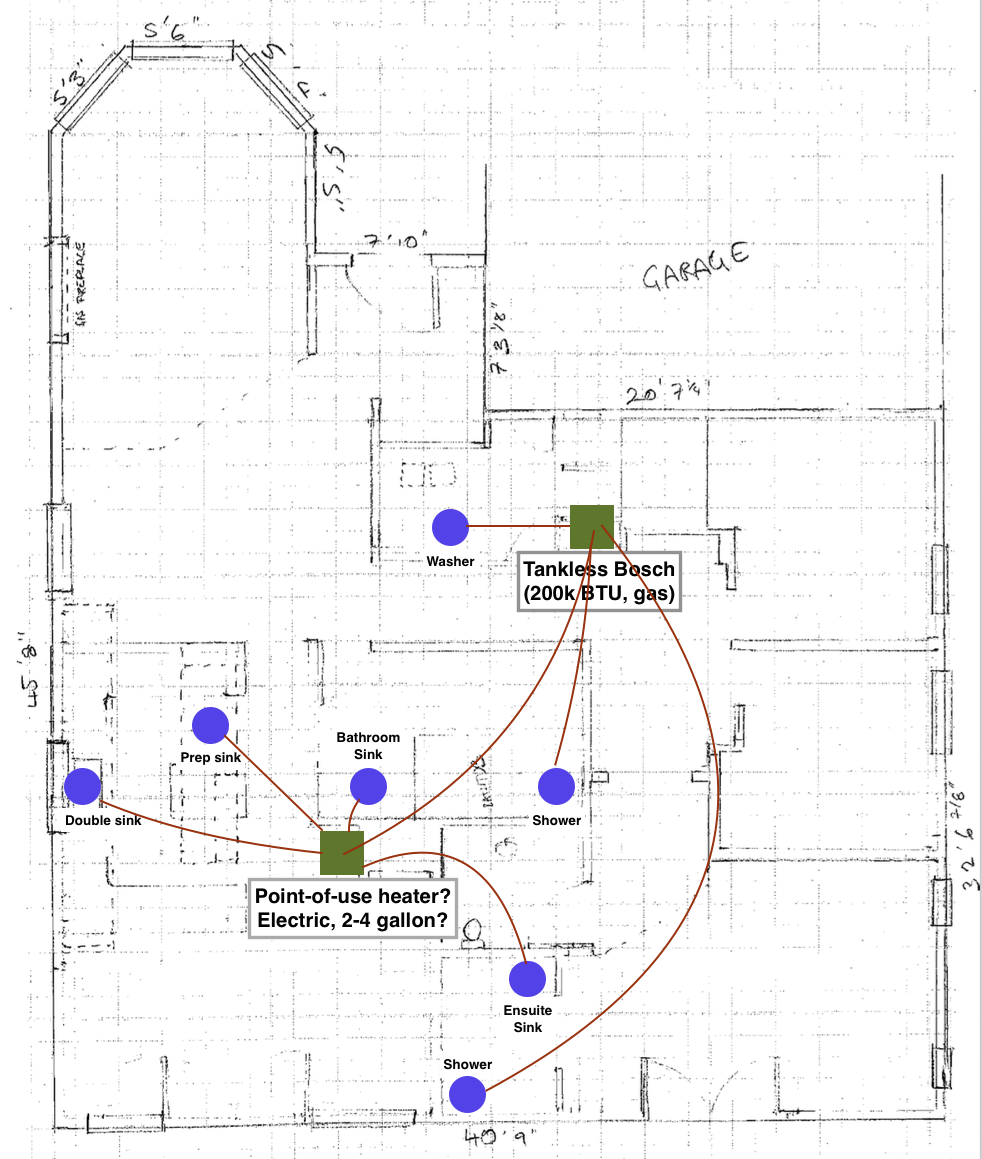

Below is a floor plan noting the locations of the sinks, showers, and the tankless system. The lower green square is where I imagine an electric point-of-use system with a small tank might help, but I don't know if this is a good idea. Feedback or other suggestions welcome!

I had a new tankless hot water system installed (a Bosch T9800, 200k BTU natural gas), and once it's fired up it does a good job of pumping out tons of hot water.

But the startup time is really disappointing - starting from a cold system and cold pipes it takes about 1 min 40 seconds to start putting out hot water from a single bathroom faucet maybe 20 feet away.

If I come back 20 minutes later it starts warm and gets hot within about 20 seconds which is fine, but if I come back an hour or two later it's ice cold again and takes 1 min 40 seconds to get hot.

What's a reasonable time to expect hot water from a modern tankless system, assuming it's installed and working well? (good gas pressure, typical piping) The house and plumbing is 30 years old, and generally well-built and cared for.

My impression is that this gas-fired tankless system is great at putting out tons of hot water when needed but takes a long time to start up and shut down, so it doesn't work very well with small volumes and random usage patterns. (e.g. washing hands for 10 seconds, or getting turned on/off frequently while rinsing dishes)

Does it sound like this system is working as designed? If so, any suggestions for what I could do to get quicker access to small volumes of hot water at sinks throughout the house?

One idea I had would be to install an electric point-of-use system with a small tank (maybe 2-4 gallons) somewhere close to all the faucets so I would always have quick access to hot water, then connect that to the big gas-fired tankless system so it's able to keep up with higher volumes when needed. Does that make sense?

There are 4 sinks where I would like to have reasonably quick access to hot water and I am hoping all of them could be fed by a single point-of-use system installed in the crawl space, rather than installing a separate one for each sink.

Below is a floor plan noting the locations of the sinks, showers, and the tankless system. The lower green square is where I imagine an electric point-of-use system with a small tank might help, but I don't know if this is a good idea. Feedback or other suggestions welcome!