SubnetMask

New Member

Our water heater is in the process of dying. If it's just the pilot light, it'll run forever, but once the main burner kicks on, and I noticed that while the burner is on, eventually, the voltage from the thermocuple starts creeping down until it gets to 9.9mv, then after sitting there for a little bit, it drops to 0 and the gas is shut off (the gas is more than likley shut off due to the voltage dropping, as that's what it's supposed to do if the flame goes out). I realize that this is probably the thermocouple, which if I can get one, would probably be like $75, but the problem is that I, like MANY people, had no idea that the WH has sacrificial anodes that are supposed to be checked/replaced AT LEAST every five years. The WH is 13 years old, never checked or replaced and the anodes are GONE (confirmed - only the stainless wire at the center remains and it was crusted with limescale), for how long, who knows. so the entire tank is suspect at this point and I don't want to put any money onto it becuase while it *might* be fine, it might also be six months away from springing a leak from internal rusting. There's no way that I'm aware of to know for sure. And there's also a TON of scale buildup inside it.

That being said, I'm looking at the Rheem ECOH200DVELN-1 to replace it. Tank water heaters are far cheaper, and some say that the savings with the tankless heaters aren't as good as they say, but for us, the tankless would give us a decent amount of reclaimed space in our rather cramped mechanical/laundry room. Plus unlimited hot water. But really, space would be a big thing.

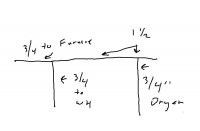

My problem & question is with gas supply. Although it hasn't been tested, I'm told by the gas company that the current supply pressure should be around 7.5 In W.C.. I have 3/4" supply line from the meter to all the way to my furnace, which is the last device in the line. The length of the run, to give a buffer, is 40' (It's actually more like 30, but I'd rather have that buffer). According to calculations, with the tankless, I'd need to supply 301,900 BTUs with the furnace, WH and dryer all running. That works out to just shy of 300CF/Hr of gas. Here's where I get lost. Two of the charts in the Rheem install manual say that I'll need either 1" or 1 1/4" pipe to get that flow rate. But they are both described as 'Inlet Pressure: Less than 2PSI' (that's real specific), one with an allowable pressure drop of 0.3 In W.C. and the other with an allowable pressure drop of 0.5. The third chart, however, is listed as 'Inlet Pressure: 8.o W.C. Inches or greater' (which is still below 2PSI and technically falls within the range of the previous two charts), and 'allowable pressure drop: 3.0 inches'. This chart lists 40' of 3/4 pipe able to carry 448CF/Hr. Plenty for all of the gas consuming appliances to run at the same time by a decent margin.

The existing appliances that would be staying are my dryer and furnace. The furnace has an inlet pressure range of 4.5-13.6, and the dryer 5.2-10.5, so that means acceptable inlet pressure range for the appliances that would be staying is 5.2-10.5, throwing out the lower of the minimums and the higher of the maximums.

So does this mean that if I have the gas company come out and increase the pressure to, say, 9.5 Inches W.C. (which is withing the acceptable range listed on the existing appliances and I was told by them they could do), will the 3/4" pipe be able to supply the ~300CF/Hr that would be required when everything is running, or is there more to it that's not listed in the install manual, and no matter what, I'd need to replace my supply line, and possibly have the gas company upgrade the meter?

That being said, I'm looking at the Rheem ECOH200DVELN-1 to replace it. Tank water heaters are far cheaper, and some say that the savings with the tankless heaters aren't as good as they say, but for us, the tankless would give us a decent amount of reclaimed space in our rather cramped mechanical/laundry room. Plus unlimited hot water. But really, space would be a big thing.

My problem & question is with gas supply. Although it hasn't been tested, I'm told by the gas company that the current supply pressure should be around 7.5 In W.C.. I have 3/4" supply line from the meter to all the way to my furnace, which is the last device in the line. The length of the run, to give a buffer, is 40' (It's actually more like 30, but I'd rather have that buffer). According to calculations, with the tankless, I'd need to supply 301,900 BTUs with the furnace, WH and dryer all running. That works out to just shy of 300CF/Hr of gas. Here's where I get lost. Two of the charts in the Rheem install manual say that I'll need either 1" or 1 1/4" pipe to get that flow rate. But they are both described as 'Inlet Pressure: Less than 2PSI' (that's real specific), one with an allowable pressure drop of 0.3 In W.C. and the other with an allowable pressure drop of 0.5. The third chart, however, is listed as 'Inlet Pressure: 8.o W.C. Inches or greater' (which is still below 2PSI and technically falls within the range of the previous two charts), and 'allowable pressure drop: 3.0 inches'. This chart lists 40' of 3/4 pipe able to carry 448CF/Hr. Plenty for all of the gas consuming appliances to run at the same time by a decent margin.

The existing appliances that would be staying are my dryer and furnace. The furnace has an inlet pressure range of 4.5-13.6, and the dryer 5.2-10.5, so that means acceptable inlet pressure range for the appliances that would be staying is 5.2-10.5, throwing out the lower of the minimums and the higher of the maximums.

So does this mean that if I have the gas company come out and increase the pressure to, say, 9.5 Inches W.C. (which is withing the acceptable range listed on the existing appliances and I was told by them they could do), will the 3/4" pipe be able to supply the ~300CF/Hr that would be required when everything is running, or is there more to it that's not listed in the install manual, and no matter what, I'd need to replace my supply line, and possibly have the gas company upgrade the meter?

Last edited: