Montreal

Member

In 2010, and again in 2022, my home insurance company is requesting that I change a perfectly working water heater.

My house has copper throughout and for the 2010 and 2022 installations, I used a 3/4" brass elbow for the bottom cold water entrance.

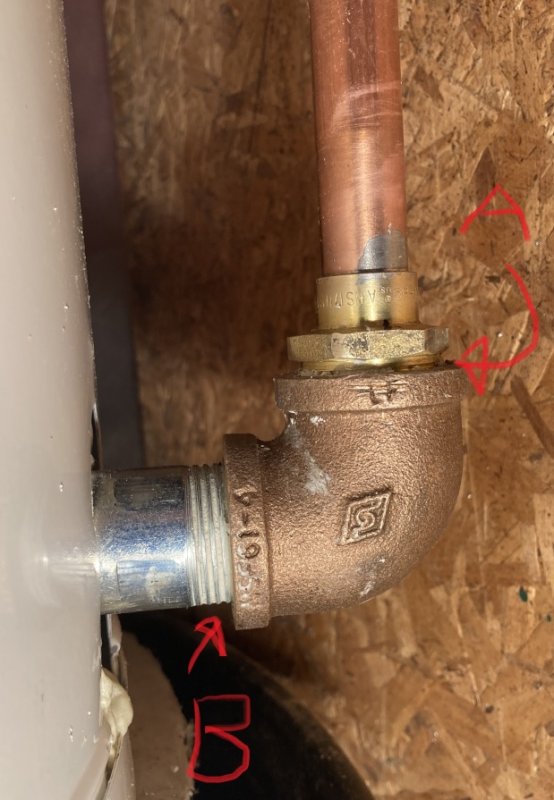

Attached is a photo showing the 2 ends of the elbow marked A and B.

For my installation, at connections A and B, I used only no-name brand teflon paste.

Connection A was tightened by wrench 1-1/8 turns after finger tight and connection B was tightened 1-1/2 turns after finger tight.

Connection A leaked immediately after installation at a rate of 1 drop a minute.

I replaced the fitting at connection A (not the elbow) using a different brand of male fitting (with a slightly longer thread), but this time I used 4 wraps of teflon tape and Megaloc paste, cranked 1-1/2 turns beyond finger tight, and this new connection is not leaking.

However, 4 hours later I took a hot shower and connection B started leaking for the first time at a rate of 1 drop an hour.

I went away for 2 days and when I returned, the leak at connection B had slowed to 1 drop every 2-3 hours.

In fact the leak is so slow, that the drop never gets big enough to fall to the ground, the lip of the elbow simply feels wet when touched by my finger tip.

I am prepared to drain the tank and install a new brass elbow and a new brass male fitting, but this time using both teflon tape and Megaloc paste at both threaded connections to the elbow.

The tank has galvanized steel di-electric nipples with rolled threads and the brass elbow has milled threads, and even with teflon tape and Megaloc paste, I am always worried that in order to get the brass elbow screwed on to point upwards to 12 o'clock, I will end up over or under tightening the elbow by plus or minus nearly one turn from what might be the optimum elbow tightness.

With a 12" wrench, I found with all these brass fittings, it is hard to wrench past 1-1/2 turns beyond finger tight. I don’t want to strip or warp the brass threads.

Any advice will be appreciated. Thanks

.

My house has copper throughout and for the 2010 and 2022 installations, I used a 3/4" brass elbow for the bottom cold water entrance.

Attached is a photo showing the 2 ends of the elbow marked A and B.

For my installation, at connections A and B, I used only no-name brand teflon paste.

Connection A was tightened by wrench 1-1/8 turns after finger tight and connection B was tightened 1-1/2 turns after finger tight.

Connection A leaked immediately after installation at a rate of 1 drop a minute.

I replaced the fitting at connection A (not the elbow) using a different brand of male fitting (with a slightly longer thread), but this time I used 4 wraps of teflon tape and Megaloc paste, cranked 1-1/2 turns beyond finger tight, and this new connection is not leaking.

However, 4 hours later I took a hot shower and connection B started leaking for the first time at a rate of 1 drop an hour.

I went away for 2 days and when I returned, the leak at connection B had slowed to 1 drop every 2-3 hours.

In fact the leak is so slow, that the drop never gets big enough to fall to the ground, the lip of the elbow simply feels wet when touched by my finger tip.

I am prepared to drain the tank and install a new brass elbow and a new brass male fitting, but this time using both teflon tape and Megaloc paste at both threaded connections to the elbow.

The tank has galvanized steel di-electric nipples with rolled threads and the brass elbow has milled threads, and even with teflon tape and Megaloc paste, I am always worried that in order to get the brass elbow screwed on to point upwards to 12 o'clock, I will end up over or under tightening the elbow by plus or minus nearly one turn from what might be the optimum elbow tightness.

With a 12" wrench, I found with all these brass fittings, it is hard to wrench past 1-1/2 turns beyond finger tight. I don’t want to strip or warp the brass threads.

Any advice will be appreciated. Thanks

.

Last edited: