I replaced the 2 ton carrier heat pump package unit with a 2 ton goodman an had a few questions on duct sizing.

The old 50s model had 14 inch ducts on unit then a reducer at duct to 12 inch flexable thru home.It had same size on return

Is that duct downsizing supposed to happen from 14 to 12?

Also the new unit has a bigger base return area with a 14 in an out ,will this cause any trouble an can i use the reducers again ?

I dont want any issues with airflow an i had to change the base on return so vent could be low enough to position unit where crawlspace opening is.

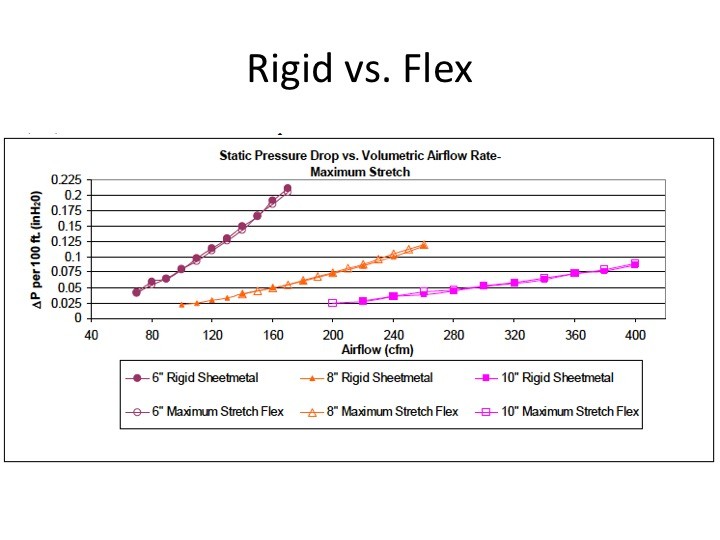

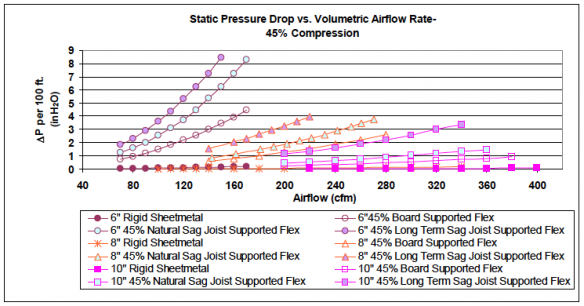

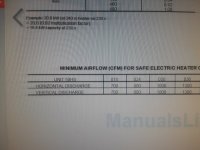

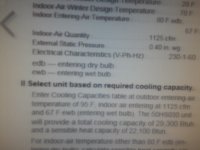

Do i need to look at the charts for cfm?

Any info is appreciated

You can see return is taller on new one.Old return an deliver were side by side both low,in diagram.

The old 50s model had 14 inch ducts on unit then a reducer at duct to 12 inch flexable thru home.It had same size on return

Is that duct downsizing supposed to happen from 14 to 12?

Also the new unit has a bigger base return area with a 14 in an out ,will this cause any trouble an can i use the reducers again ?

I dont want any issues with airflow an i had to change the base on return so vent could be low enough to position unit where crawlspace opening is.

Do i need to look at the charts for cfm?

Any info is appreciated

You can see return is taller on new one.Old return an deliver were side by side both low,in diagram.

Attachments

Last edited: