Yukoner777

Member

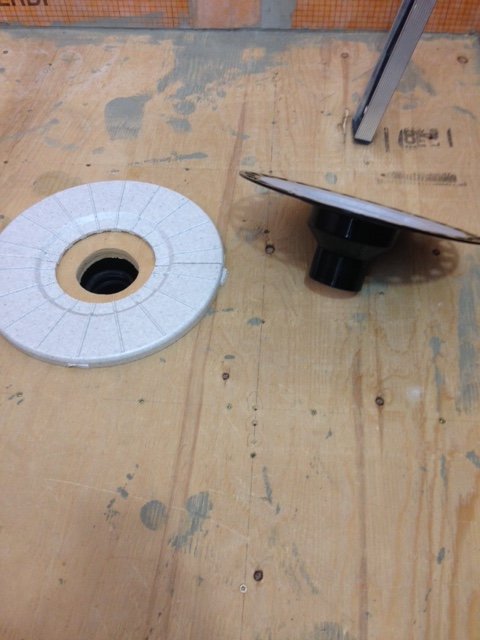

Way back at the beginning of my bathroom project, I raised the floor for my 4' x 4' tiled shower, in order to accommodate the proper slope for the drain and the trap. I bought the pre-sloped Kerdi shower pan with drain kit. Unfortunately for me, I didn't research the drain kit before building and it looks like the drain kit requires the top of the drain to be a minimum of 3 1/4" below the floor. As you can see from my pics, the top of the abs drainpipe is only 1 1/2" down from the top of the plywood floor.

At this point, I'm thinking I could add two sheets of 7/8" plywood to the shower floor. But with the combined thickness of the plywood and the shower pan, that would only leave me a little over half an inch height of my curb, so that would have to be raised, which in turn makes the step over the curb into the shower go from 6" high to about 8 or 9" high.

Are there any other drain options where I could still use the Kerdi shower pan? Or am I now faced with having to do a mortar bed shower pan and selling the Kerdi pan?

Other suggestions?

Thanks

Ross

At this point, I'm thinking I could add two sheets of 7/8" plywood to the shower floor. But with the combined thickness of the plywood and the shower pan, that would only leave me a little over half an inch height of my curb, so that would have to be raised, which in turn makes the step over the curb into the shower go from 6" high to about 8 or 9" high.

Are there any other drain options where I could still use the Kerdi shower pan? Or am I now faced with having to do a mortar bed shower pan and selling the Kerdi pan?

Other suggestions?

Thanks

Ross