Hello,

I hope someone is able to assist and give advice. I am trying to get a plumber out to quote or even sell me design specs but it is like pulling teeth. I didn't want to run the plumbing but it is looking more and more like I might have to.

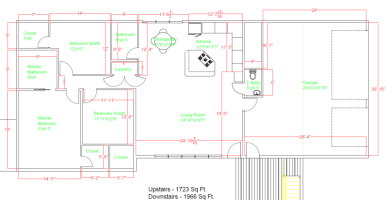

I am trying to move forward on my second floor/roof. The ides is to run all plumbing north (top) out of the house and then into a 3" along building to meet up with the 3" that is on the east side. My existing roof is a concrete slab with 3-4" xps foam. I will attempt to keep the foam and add dirt/rock as needed. We will pour a slab on top of this so I need to know if possible:

1) how much space do I need between the two slabs for the DWV traps and fall?

2)Should I attempt to combine under the new slab or just run each individual line out?

3)How far away from each fixture would I need a vent?

4)Can I combine vents in attic?

5)How big should floor drains be for the Washer, Dishwasher, utility room (Water softener, Filters, HVAC drains). These will probably go to daylight unless there is a large objection.

--Water in and Hot water heater will be behind 1/2 Bath and Kitchen. For each area (#6,#7,#8) I will have an accessible manifold in the wall to junction off to each fixture.

6)Water will be PEX-A. 1" cold for 1/2 bath and Kitchen.

7)1"cold and Hot for Laundry, main bath.

8)1" cold and Hot for Master Bath.

9) 3/4 hot return from each area for quicker hot water.

Any help/advice/ is MUCH appreciated.

I hope someone is able to assist and give advice. I am trying to get a plumber out to quote or even sell me design specs but it is like pulling teeth. I didn't want to run the plumbing but it is looking more and more like I might have to.

I am trying to move forward on my second floor/roof. The ides is to run all plumbing north (top) out of the house and then into a 3" along building to meet up with the 3" that is on the east side. My existing roof is a concrete slab with 3-4" xps foam. I will attempt to keep the foam and add dirt/rock as needed. We will pour a slab on top of this so I need to know if possible:

1) how much space do I need between the two slabs for the DWV traps and fall?

2)Should I attempt to combine under the new slab or just run each individual line out?

3)How far away from each fixture would I need a vent?

4)Can I combine vents in attic?

5)How big should floor drains be for the Washer, Dishwasher, utility room (Water softener, Filters, HVAC drains). These will probably go to daylight unless there is a large objection.

--Water in and Hot water heater will be behind 1/2 Bath and Kitchen. For each area (#6,#7,#8) I will have an accessible manifold in the wall to junction off to each fixture.

6)Water will be PEX-A. 1" cold for 1/2 bath and Kitchen.

7)1"cold and Hot for Laundry, main bath.

8)1" cold and Hot for Master Bath.

9) 3/4 hot return from each area for quicker hot water.

Any help/advice/ is MUCH appreciated.