I've run into my first customer with significant tds. I believe the last two companies I worked for were not approaching these situations correctly, so I'm looking for some input. His TDS is 1640 at the tap with softened water feeding, (what will be) an under sink (POU) RO. the water temperature is around 45+- degrees and PT at 40/60 with 3 people in the home (which equals around 9 gallons of RO water use per day). Would you recommend a 50gpd RO with a booster pump or can I get by with a 100gpd membrane.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ro booster pump vs membrane rate

- Thread starter Water Pro

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Scottp999

New Member

Interesting situation. No recommendations, but watching. We have 2 adults, 2 children, tds 350-450, and I experimented with 100GPD, 75GPD, and 50GPD and various flow restrictors for the drain side. 50GPD turned out best. My guess is that the 50GPD produces water more slowly and there is less TDS creep as the tank is filling. Just a guess, but that is what worked best for us. We probably use between 3-6 gallons per day. I also dump the tank water every 14 days or so to prevent TDS creep (4 gallon tank that maybe holds 2.2 gallons of water). Settled on a 550ml flow restrictor and we see in between 90-97% TDS reduction. Get less efficient as the tank pressure starts to push back on the incoming water pressure.

Sponsor

Paid Advertisement

Bannerman

Well-Known Member

RO production rate is the product of many variables including TDS, water temperature, pressure differential across the membrane and back pressure from water in storage.Get less efficient as the tank pressure starts to push back on the incoming water pressure.

An RO membrane will work best with high pressure across it. A consistent feed pressure of ~80 psi is usually recommended, but 60 psi and up is usually sufficient for most undersink household drinking water applications.

One method to eliminate back pressure on the membrane and increase the pressure differential is to install a permeate pump which will interface between the membrane and storage tank. Lower back pressure on the membrane will increase the production rate and reduce the run time to fill the storage tank so there will be less brine water sent to drain.

A standard ASV will stop production once the pressure of permeate water in storage is approx 60% of the feed pressure. In using a permeate pump, the standard ASV maybe eliminated or replaced with a high pressure ASV which will allow the storage tank pressure to exceed 90% of feed pressure.

Last edited:

thank you bannerman. I'm familiar with the permeate pumps, but wasn't sure I should go that route as, from what I gather, they can increase tds creep. as I suspected, I believe my previous employer was approaching this incorrectly, they believed a booster pump was the answer to increase production, even when incoming pressure averaged 50 psi. it never seemed to do much of anything with regards to increasing production. my next question is this, these units are tested at 72°F and, from what I understand, lose 2% efficiency for every degree below that. So if I had a temp of 45°, I would be expected to lose 54% efficiency? will the addition of high tds, even with the permeate pump, allow me to produce sufficient permeate to reach the 9 gpd that I'm looking for if using a 50 gpd membrane or should I go with a 75 or 100 gpd combined with the permeate pump?RO production rate is the product of many variables including TDS, water temperature, pressure differential across the membrane and back pressure from water in storage.

An RO membrane will work best with high pressure across it. A consistent feed pressure of ~80 psi is usually recommended, but 60 psi and up is usually sufficient for most undersink household drinking water applications.

One method to eliminate back pressure on the membrane and increase the pressure differential is to install a permeate pump which will interface between the membrane and storage tank. Lower back pressure on the membrane will increase the production rate and reduce the run time to fill the storage tank so there will be less brine water sent to drain.

A standard ASV will stop production once the pressure of permeate water in storage is approx 60% of the feed pressure. In using a permeate pump, the standard ASV maybe eliminated or replaced with a high pressure ASV which will allow the storage tank pressure to exceed 90% of feed pressure.

In looking around, I found these... not directly addressing your question, but still potentially useful:

https://www.appliedmembranes.com/reverse-osmosis-membranes-and-systems-for-low-tap-pressures.html

https://wateranywhere.com/faqs/ro-membranes/ says that if no chlorine, use film type filter. If chlorine present, use CTA type.

https://www.appliedmembranes.com/reverse-osmosis-membranes-and-systems-for-low-tap-pressures.html

https://wateranywhere.com/faqs/ro-membranes/ says that if no chlorine, use film type filter. If chlorine present, use CTA type.

great info! thanks reachIn looking around, I found these... not directly addressing your question, but still potentially useful:

https://www.appliedmembranes.com/reverse-osmosis-membranes-and-systems-for-low-tap-pressures.html

https://wateranywhere.com/faqs/ro-membranes/ says that if no chlorine, use film type filter. If chlorine present, use CTA type.

from what I'm reading I would need to apply roughly an extra 17 lbs of pressure to overcome the osmotic pressure of 1700 tds and still equal the mean pressure of 50 psi. On top of that, with a 40/60 pressure switch, there might be times that the feed pressure may be nearer the 40 psi mark for extended periods of time. so I guess I do need a booster pump. wonder if I should also include the permeate pump as that will increase flow at the faucet and increase storage, or just add another pressure tank in series if they complaint about low flow.

..thank you bannerman. I'm familiar with the permeate pumps, but wasn't sure I should go that route as, from what I gather, they can increase tds creep. as I suspected, I believe my previous employer was approaching this incorrectly, they believed a booster pump was the answer to increase production, even when incoming pressure averaged 50 psi. it never seemed to do much of anything with regards to increasing production. my next question is this, these units are tested at 72°F and, from what I understand, lose 2% efficiency for every degree below that. So if I had a temp of 45°, I would be expected to lose 54% efficiency? will the addition of high tds, even with the permeate pump, allow me to produce sufficient permeate to reach the 9 gpd that I'm looking for if using a 50 gpd membrane or should I go with a 75 or 100 gpd combined with the permeate pump?

thank you.Interesting situation. No recommendations, but watching. We have 2 adults, 2 children, tds 350-450, and I experimented with 100GPD, 75GPD, and 50GPD and various flow restrictors for the drain side. 50GPD turned out best. My guess is that the 50GPD produces water more slowly and there is less TDS creep as the tank is filling. Just a guess, but that is what worked best for us. We probably use between 3-6 gallons per day. I also dump the tank water every 14 days or so to prevent TDS creep (4 gallon tank that maybe holds 2.2 gallons of water). Settled on a 550ml flow restrictor and we see in between 90-97% TDS reduction. Get less efficient as the tank pressure starts to push back on the incoming water pressure.

Bannerman

Well-Known Member

With 40 psi feed pressure, the storage tank pressure will be only 24 psi so the quantity of permeate in storage will also be lower.

Running an electric booster pump will optimize the feed pressure regardless of the fluctuations of the well system pressure. This will not only increase the quantity of water in storage and increase the pressure at the RO faucet, but also improve the quality of the permeate.

Using also a permeate pump will further increase the production rate to be more consistent to the membrane capacity rating.

Running an electric booster pump will optimize the feed pressure regardless of the fluctuations of the well system pressure. This will not only increase the quantity of water in storage and increase the pressure at the RO faucet, but also improve the quality of the permeate.

Using also a permeate pump will further increase the production rate to be more consistent to the membrane capacity rating.

thank you bannerman. two things I'm still unclear of. The aquatech manual statesWith 40 psi feed pressure, the storage tank pressure will be only 24 psi so the quantity of permeate in storage will also be lower.

Running an electric booster pump will optimize the feed pressure regardless of the fluctuations of the well system pressure. This will not only increase the quantity of water in storage and increase the pressure at the RO faucet, but also improve the quality of the permeate.

Using also a permeate pump will further increase the production rate to be more consistent to the membrane capacity rating.

"POSITIVE INLET PRESSURE WILL INCREASE THE DISCHARGE PRESSURE BY A SIMILAR AMOUNT FOR A GIVEN FLOW." does this mean the pump would only have to add 60 psi if the incoming pressure was at 60 psi to achieve 120 psi? or is the feed pressure separate from the outlet pressure? which brings me to my second question, I see that optimal tds reduction rate is 98% at 120 psi. are ROs tested at 60 psi for a reason?

Last edited:

Bannerman

Well-Known Member

The spec page for the 8800 series pump states as you said, but it also specifies a maximum inlet pressure of 60 psi and recommends limiting the outlet pressure to a maximum 110 psi by use of an appropriate bypass valve.

The Aquatec booster pump pressure switches are typically calibrated to limit the pump's outlet pressure to 80 psi regardless of inlet pressure. I suspect this will be due to so many low quality RO units offered which are likely to fail if the inlet pressure should exceed 80 psi.

I anticipate 60 psi membrane ratings are often specified as that is a common pressure for a municipal water system or when using a PRV. Because most residential apllications at that pressure will likely not use a booster pump, 60 psi specifications will apply to many users.

Although Dow Filmtec CSM membranes specify up to 98% rejection at 60 psi (@ 200 ppm TDS), the specified maximum operating pressure is 150 psi so they are likely tested to at least 300 psi before failure is expected.

The Aquatec booster pump pressure switches are typically calibrated to limit the pump's outlet pressure to 80 psi regardless of inlet pressure. I suspect this will be due to so many low quality RO units offered which are likely to fail if the inlet pressure should exceed 80 psi.

I anticipate 60 psi membrane ratings are often specified as that is a common pressure for a municipal water system or when using a PRV. Because most residential apllications at that pressure will likely not use a booster pump, 60 psi specifications will apply to many users.

Although Dow Filmtec CSM membranes specify up to 98% rejection at 60 psi (@ 200 ppm TDS), the specified maximum operating pressure is 150 psi so they are likely tested to at least 300 psi before failure is expected.

I didn't even think of factoring in the pressure switch as a limiter, but it makes total sense, as most of these 50-150 gpd POU systems are max rated to between 80 and 100 psi. you rock. im thinking of sticking with the 6800, but may consider the 8800, not sure yet. I'll do more research on that and the thin film membranes tomorrow. learning a lot. thanks again.The spec page for the 8800 series pump states as you said, but it also specifies a maximum inlet pressure of 60 psi and recommends limiting the outlet pressure to a maximum 110 psi by use of an appropriate bypass valve.

The Aquatec booster pump pressure switches are typically calibrated to limit the pump's outlet pressure to 80 psi regardless of inlet pressure. I suspect this will be due to so many low quality RO units offered which are likely to fail if the inlet pressure should exceed 80 psi.

I anticipate 60 psi membrane ratings are often specified as that is a common pressure for a municipal water system or when using a PRV. Because most residential apllications at that pressure will likely not use a booster pump, 60 psi specifications will apply to many users.

Although Dow Filmtec CSM membranes specify up to 98% rejection at 60 psi (@ 200 ppm TDS), the specified maximum operating pressure is 150 psi so they are likely tested to at least 300 psi before failure is expected.

Last edited:

Scottp999

New Member

RO production rate is the product of many variables including TDS, water temperature, pressure differential across the membrane and back pressure from water in storage.

An RO membrane will work best with high pressure across it. A consistent feed pressure of ~80 psi is usually recommended, but 60 psi and up is usually sufficient for most undersink household drinking water applications.

One method to eliminate back pressure on the membrane and increase the pressure differential is to install a permeate pump which will interface between the membrane and storage tank. Lower back pressure on the membrane will increase the production rate and reduce the run time to fill the storage tank so there will be less brine water sent to drain.

A standard ASV will stop production once the pressure of permeate water in storage is approx 60% of the feed pressure. In using a permeate pump, the standard ASV maybe eliminated or replaced with a high pressure ASV which will allow the storage tank pressure to exceed 90% of feed pressure.

Thanks. I'm using a premeate pump and the high pressure ASV. Aquatec ERP-500 + AFW ASV90 ASV90-14Q 90% Auto Shut Off Valve for reverse osmosis ASV for RO with permeate pump.

doesn't the ERP shut off feed water? or is the ASO required in addition?Thanks. I'm using a premeate pump and the high pressure ASV. Aquatec ERP-500 + AFW ASV90 ASV90-14Q 90% Auto Shut Off Valve for reverse osmosis ASV for RO with permeate pump.

ditttohead

Water systems designer, R&D

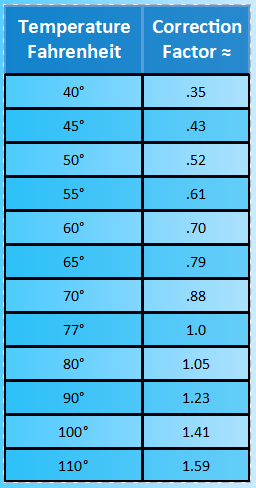

I did not read the entire post... but 1700 TDS is not too crazy. Assuming you are on a well, the most common design is a simple RO with a booster pump which will increase the pressure on the front side of the membrane to 80 PSI. Lower water temperatures will significantly reduce production so be sure to factor that in. Here is a simple temperature compensation chart I made a while back, it is fairly accurate. At 50F, a 100 GPD RO will produce about 60 GPD. Add in the additional RO pressure of 15 PI over membrane rating, but take away the loss for high TDS... you will be very near the same... 60 GPD. Here is a popular booster pump design we make using an Aquatec USA booster pump, and with a nice pump mounting bracket.

Scottp999

New Member

doesn't the ERP shut off feed water? or is the ASO required in addition?

1) Correct, 2) Not Required.

I was doing a lot of testing on TDS creep in the tank from water pressure across the membrane vs. back pressure from the holding tank. Best result for me was to add the 90% ASO. Theoretically, that stops the water flow before the ERP-500 so there is less back pressure from the tank...this also means i lose a bit of pressure at the tap, but it is still good (I'm feeding just a water dispenser and ice maker at the fridge, no dispenser at the sink). My incoming water pressure to the system is around 70-72psi. If the ASO also lets more water come out of the holding tank before the system starts to fill it again, then there is less back pressure at that time as well.

ditttohead

Water systems designer, R&D

Actually that is not why the 90% prevents TDS creep. The PP "hides" the backpressure from the tank so with or without the ASV the system will operate the same. The real advantage of the ASV is primarily in low use applications. The 90% ASV shuts of at 90% and reopens at approximately 70% of line pressure. Without the ASV, if you take a glass of water out of the tank, it will likely fill the tank back up right away. The water sitting in the membrane will start the unique process of osmosis... where the higher concentration water will start to osmose across the membrane. This is why so many "tankless" Ro's have such a bad reputation. The first glass of water is high TDS unless you do a permeate purge after the system shuts down, which tends to waste a lot of water especially in frequent low use applications... sorry very wonky stuff here, but I just wanted to correct the assumption of why the 90% ASV mitigates TDS creep. Simply put, the first dose of water coming out of the membrane after the ro ha sat idle for a little while will have higher tds, the storage tanks dilutes his out to barely noticeable levels. Without an ASV, this problem can become worse and can result in a noticeably higher TDS especially in low use applications. In high use applications, the effect is mitigated substantially. Hope this helps.

Scottp999

New Member

Actually that is not why the 90% prevents TDS creep. The PP "hides" the backpressure from the tank so with or without the ASV the system will operate the same. The real advantage of the ASV is primarily in low use applications. The 90% ASV shuts of at 90% and reopens at approximately 70% of line pressure. Without the ASV, if you take a glass of water out of the tank, it will likely fill the tank back up right away. The water sitting in the membrane will start the unique process of osmosis... where the higher concentration water will start to osmose across the membrane. This is why so many "tankless" Ro's have such a bad reputation. The first glass of water is high TDS unless you do a permeate purge after the system shuts down, which tends to waste a lot of water especially in frequent low use applications... sorry very wonky stuff here, but I just wanted to correct the assumption of why the 90% ASV mitigates TDS creep. Simply put, the first dose of water coming out of the membrane after the ro ha sat idle for a little while will have higher tds, the storage tanks dilutes his out to barely noticeable levels. Without an ASV, this problem can become worse and can result in a noticeably higher TDS especially in low use applications. In high use applications, the effect is mitigated substantially. Hope this helps.

Appreciate that level of detail. Thanks.

you could roughly double your pressure at the tap and double your storage capacity if you add another pressure tank in series.1) Correct, 2) Not Required.

I was doing a lot of testing on TDS creep in the tank from water pressure across the membrane vs. back pressure from the holding tank. Best result for me was to add the 90% ASO. Theoretically, that stops the water flow before the ERP-500 so there is less back pressure from the tank...this also means i lose a bit of pressure at the tap, but it is still good (I'm feeding just a water dispenser and ice maker at the fridge, no dispenser at the sink). My incoming water pressure to the system is around 70-72psi. If the ASO also lets more water come out of the holding tank before the system starts to fill it again, then there is less back pressure at that time as well.

Similar threads

- Replies

- 7

- Views

- 900

- Replies

- 13

- Views

- 783

- Replies

- 1

- Views

- 298

- Replies

- 5

- Views

- 607