Is that a Clack RT120? Then one connection on top is labeled "Upflow Inlet", and that is connected to the dip tube. That I think is where the vacuum breaker is. The other port is the output, and is labeled "Downflow Inlet". I am trying to think if there would be an advantage to connecting the vacuum breaker to one port or the other, but I can't figure a significant advantage.

I still can't drain my retention tank without it collapsing.

Are you referring to opening the blow down port to drain sediment away? That would normally be done with the tank under pressure, with the pump kicking on as the pressure dropped.

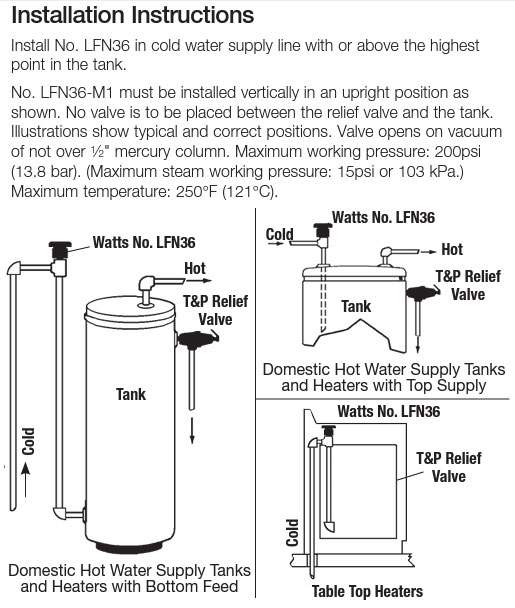

If you were draining it empty with the pump off, the vacuum breaker should let the air in. I see the price of vacuum breakers increases quickly with size. Still, I would think that your 3/4 vacuum breaker should be able to admit air as quickly as you could drain water out. I don't know what causes your problem, unless your vacuum breaker is defective. Did you suck on it to see if it admitted air?

You need to protect those unpainted tanks, softener controller, and the PVC pipe from UV with a cover or paint.