dieselfuelonly

New Member

Hey all, I'm located in NC and have a 1989 1000sq ft double wide manufactured home that I intend on replacing the polybutylene pipe with PEX. With the exception of underneath the laundry room on one end of the home, the underbelly is mostly intact and I'd love to keep it that way.

Just looking for advice on the best way to go about replumbing this house. I have a 1000sq ft garage that butts up against one side of the house that I currently have a 500 gallon storage tank for a low-yield well in, and I'd like to move the water heater there as well during this process and possibly add a recirculation line.

All the plumbing is on one half of the house.

So far I've seen 4 main options:

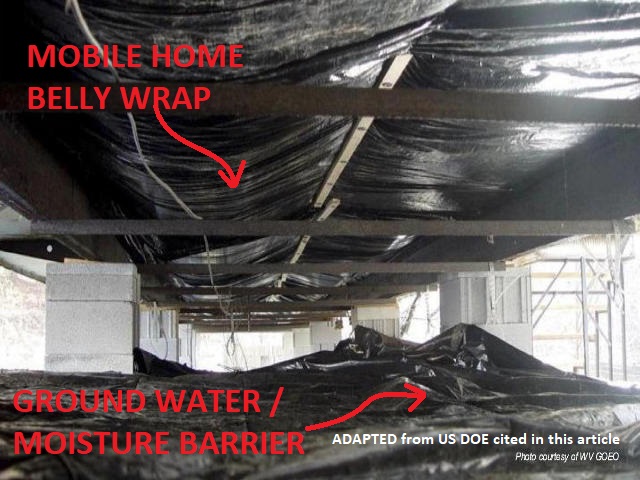

1. Cut holes in the underbelly to fish the PEX through above the underbelly/insulation, cutting large enough holes to make all the crimps teeing off the main 3/4" lines. Then repair the underbelly the best I can.

2. Remove the whole underbelly and make a new one that hangs underneath. Much easier said than done, although it would make the plumbing itself MUCH easier.

3. Cut strategic holes in the floor and fish the PEX through from above. All of the flooring I would be cutting is is linoleum, so a new piece would have to be put down in the rooms. Some rooms just have the little stick-on tiles which would make this somewhat easier to repair, others not. This would require at least 4-5 holes in the floors and I guess just hoping I cut in the right spot (appears the existing plumbing is run along side the heating duct on one side).

4. Run the PEX below the underbelly and do all the teeing off underneath, then stab directly up through the underbelly to where the connections need to be made. Easier to plumb and less damage to the underbelly, but would require all the PEX to be insulated plus heat tape maybe as the winters here can get down in the teens.

Honestly, since I'm on well water the polyb pipe has held up fine. But the flow to many of the fixtures sucks as it's only 3/8" pipe. I figure I'll have to replace it all at some point anyway, so might as well have a plan before something major finally goes.

Thanks for any advice.

Just looking for advice on the best way to go about replumbing this house. I have a 1000sq ft garage that butts up against one side of the house that I currently have a 500 gallon storage tank for a low-yield well in, and I'd like to move the water heater there as well during this process and possibly add a recirculation line.

All the plumbing is on one half of the house.

So far I've seen 4 main options:

1. Cut holes in the underbelly to fish the PEX through above the underbelly/insulation, cutting large enough holes to make all the crimps teeing off the main 3/4" lines. Then repair the underbelly the best I can.

2. Remove the whole underbelly and make a new one that hangs underneath. Much easier said than done, although it would make the plumbing itself MUCH easier.

3. Cut strategic holes in the floor and fish the PEX through from above. All of the flooring I would be cutting is is linoleum, so a new piece would have to be put down in the rooms. Some rooms just have the little stick-on tiles which would make this somewhat easier to repair, others not. This would require at least 4-5 holes in the floors and I guess just hoping I cut in the right spot (appears the existing plumbing is run along side the heating duct on one side).

4. Run the PEX below the underbelly and do all the teeing off underneath, then stab directly up through the underbelly to where the connections need to be made. Easier to plumb and less damage to the underbelly, but would require all the PEX to be insulated plus heat tape maybe as the winters here can get down in the teens.

Honestly, since I'm on well water the polyb pipe has held up fine. But the flow to many of the fixtures sucks as it's only 3/8" pipe. I figure I'll have to replace it all at some point anyway, so might as well have a plan before something major finally goes.

Thanks for any advice.