I'm renovating the bath in an early-70s condo that's got mostly floor-mount/wall-outlet toilets. With the formerly-rotten wall open and the steel flange a lot cleaner than I found it, I can see that the plane of the flange is noticeably shifted from the plane of the wall. It's probably not so far out of parallel that the new neoprene gasket can't handle it. But there are three stainless bolt-heads counterbored into the face of the flange, and they're just begging for me to use them to adjust that flange back to parallel - if I dare.

I didn't touch it yet because I have NO idea what seals the inner lip of the flange to the rest of the bend. And no, I definitely don't want to break that seal by getting too anal-retentive about parallelism, even if that seal is composed entirely of aged excrement at this point. It's as crusty and nasty as you'd expect of a 44-year-old poo-portal, so if I broke the seal, I'd be getting a LOT more intimate with that crud than I'd like, while trying to fix it.

Can anyone say what sealed these between flange and the rest of the bend, to begin with? Were they built with O-rings, maybe? I wasn't able to Google up a representative example, but it's a 3" CI bend with the wall-flange adapted to it, and a 2" vent outlet topside (probably very common in highrise DWV...?)

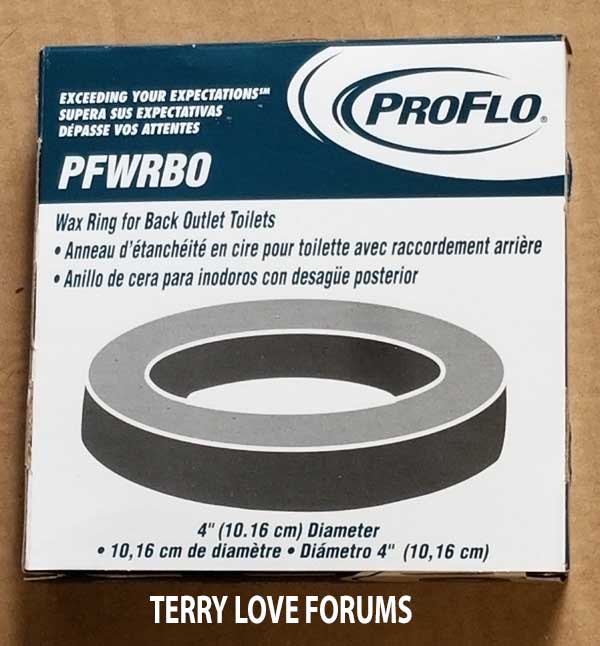

Related question: is it in some jurisdictions prohibited to use wax gaskets on wall-outlet toilets, with or without felt? I'd never want to use one except in an extreme pinch, but have run into plumbers that do so without any concern.

Tx - Dave

I didn't touch it yet because I have NO idea what seals the inner lip of the flange to the rest of the bend. And no, I definitely don't want to break that seal by getting too anal-retentive about parallelism, even if that seal is composed entirely of aged excrement at this point. It's as crusty and nasty as you'd expect of a 44-year-old poo-portal, so if I broke the seal, I'd be getting a LOT more intimate with that crud than I'd like, while trying to fix it.

Can anyone say what sealed these between flange and the rest of the bend, to begin with? Were they built with O-rings, maybe? I wasn't able to Google up a representative example, but it's a 3" CI bend with the wall-flange adapted to it, and a 2" vent outlet topside (probably very common in highrise DWV...?)

Related question: is it in some jurisdictions prohibited to use wax gaskets on wall-outlet toilets, with or without felt? I'd never want to use one except in an extreme pinch, but have run into plumbers that do so without any concern.

Tx - Dave

Last edited by a moderator: