Topgun510

New Member

Hello everyone,

Looks like every ten years or so I find myself on this forum asking for help. A decade ago it was the septic, drain pipe. Now we are dealing with what I suspect is a failed check valve or pipe in the well. Having the capability of hearing mouse fart has its pros and cons, I hear everything. When the well pump went off more than usual despite no water being used and the wife acknowledged the laundry was NOT running, I knew we had a problem. After a check of all the faucets and pipes revealed no leaks, I pretty much arrived at the conclusion that this in a problem on the inlet side, pump, pipe and check valve.

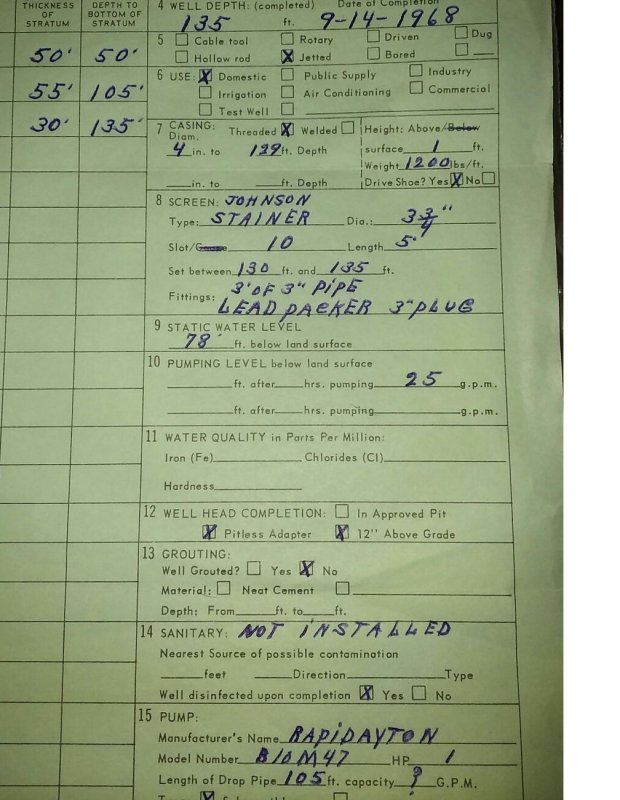

Looking at the documentation the previous owners left us from the well install isn't very comforting. The pump is 135' down. Looking at the cap of the well, hhmm, how the hell am I even going to be able to take this thing off? So, before I do anything I'll later regret, I figured I'd come on here and seek out some advice from you guys. Having been put in back in 1968, what is the likelihood of the pipe being galvanized vs polyethelene?? I have called a local professional and am currently awaiting a call back. Any advice you all have is welcomed. I've shut the breaker off in the meantime.

Looks like every ten years or so I find myself on this forum asking for help. A decade ago it was the septic, drain pipe. Now we are dealing with what I suspect is a failed check valve or pipe in the well. Having the capability of hearing mouse fart has its pros and cons, I hear everything. When the well pump went off more than usual despite no water being used and the wife acknowledged the laundry was NOT running, I knew we had a problem. After a check of all the faucets and pipes revealed no leaks, I pretty much arrived at the conclusion that this in a problem on the inlet side, pump, pipe and check valve.

Looking at the documentation the previous owners left us from the well install isn't very comforting. The pump is 135' down. Looking at the cap of the well, hhmm, how the hell am I even going to be able to take this thing off? So, before I do anything I'll later regret, I figured I'd come on here and seek out some advice from you guys. Having been put in back in 1968, what is the likelihood of the pipe being galvanized vs polyethelene?? I have called a local professional and am currently awaiting a call back. Any advice you all have is welcomed. I've shut the breaker off in the meantime.

Last edited: