Even a fairly air-leaky version of a 2400' slab on grade 2x4/R13 two story with more than the typical square footage of U0.5 clear glass (not low-E) double-panes would have a heat load in the 30,000 BTU/hr range @ 25F. A 1.4x oversizing factor would bump that to the 40K range.

A $400 @ $0.10/kwh is 4000 kwh/month. A typical December-January monthly heating degree days in the Dallas area is 550-600 HDD (base 65F.) Call it 4000 kwh over 550HDD- that's 7.3 kwh per degree-day, or (/24=) 0.30 kwh per degree-hour. 1kwh =3412 BTU, so for a linear estimate for every degree below the 65F presumptive balance point the load increases by (0.30 x 3412=) 1024 BTU/hr (which is really high for a house that size).

The 99% design temperature is about 25F, which is (65F - 25F =) 40F heating degrees under the presumptive heating/cooling balance point. So the implied load is then

1024BTU/degree-hour x 40F = 41,000 BTU/hr

Odds are pretty good that at least 10% of that power use was heating hot water that went down the drain instead of heating the house, so call it 37,000 BTU/hr. The ASHRAE recommended max 1.4x factor would put the furnace sizing at 1.4 x 37KBTU/hr = 52KBTU/hr.

The AFUE-tested 1.7x oversize factor would be 1.7 x 37K = 63K, which would enough furnace to keep the place warm well into negative double digits F!

So a 50-60 condensing furnace (or 3 to 3.5 ton heat pump w/resistance strip heat backup) would be the most furnace this place would ever need.

Having lots of extra glass (especially west-facing) can increase the peak cooling load, but being multi-story usually reduces it relative to a single story ranch house, due to fewer square feet hot roof overhead. Most homes of that vintage and size would have a cooling tonnage per floor area ratio on the order of ton per 1000' of conditioned space, but it varies quite a bit, which would put your house in the 2.5 ton range, but possibly higher. Putting insulated ducts & air handlers in the attic above he insulation adds about a half ton or so of load, so a 3.5 ton compressor wouldn't be ridiculously oversized, but a 5 tonner almost surely would be. An

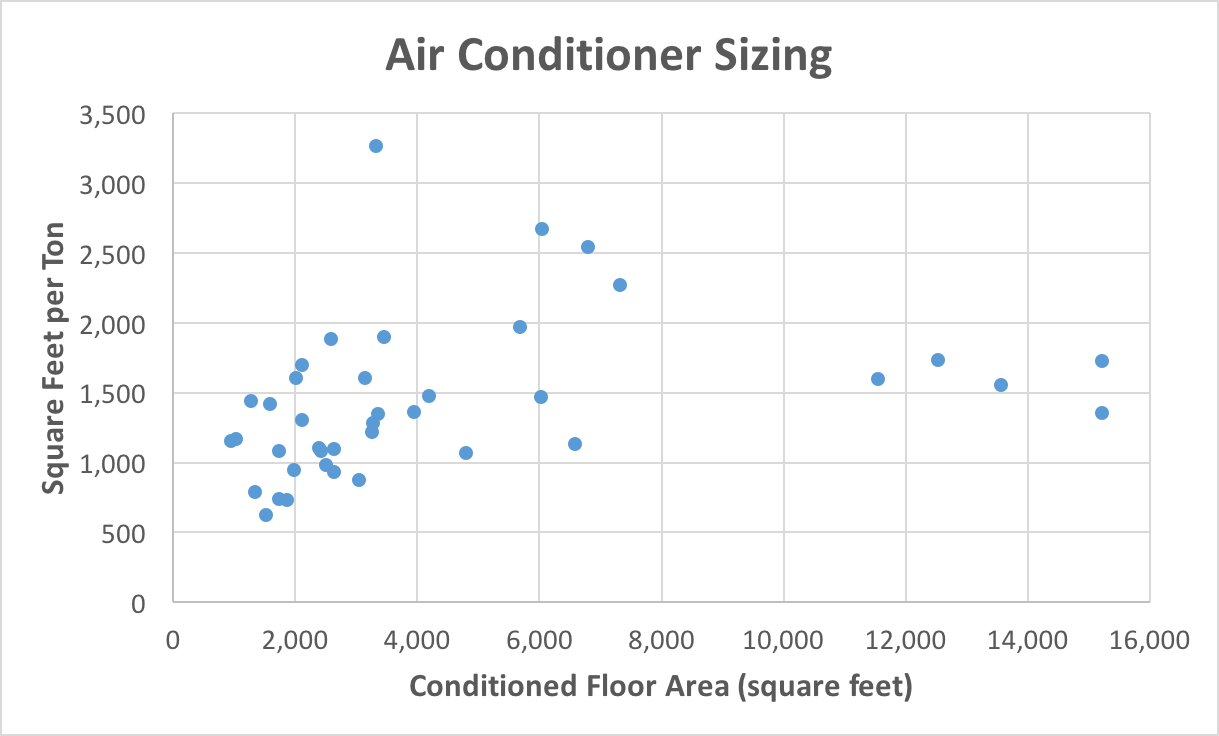

outfit in the Atlanta area that does HVAC design and careful Manual-J load calculations all over the US (but mostly in the gulf coast states) compiled this graph of square feet per ton, against house size, based on the actual Manual-J cooling load calculations of their clients, with houses of all types & vintage:

If you look at the cluster in the 2400' house size range the worst of them is about a ton per 800', which if that were your house would be a 3 ton load. The middle of the cluster is about a ton per 1200-1400', which would be about a 2 ton load.

I suspect a 2-stage (or modulating) 3 ton heat pump with heat strips to cover the Polar Vortex cold snaps depths is really the right solution here, but getting better load numbers could fine tune it. That company

Energy Vanguard runs those numbers and specs the equipment for a fee. There are others in that business too, probably some more local to you. Just be sure to use a company that makes their living off of accurate numbers, not an HVAC company whose bread & butter is installing and maintaining equipment. Odds are pretty good that most of the fee would be recouped in lower cost smaller equipment now, and higher as-used efficiency (and higher comfort levels) down the road.