SuperGreg

Member

Hello all, I've been lurking for a bit as I've been planning big changes to my well filters. Finally got around to redoing the system this last weekend and the job was 3x bigger than I thought, so I just finished yesterday. Unfortunately all is not well and I'm running into several issues keeping me from getting water back on in the house.

Some small background first:

I guess the main issue is my well is a piece of crap - it is *very* silty, and if the pump is run continuously for say 10 minutes the water coming out looks like chocolate milk. The old system had a Harmsco unit with 7 canister filters inside, then a big blue, then an ultrafilter. Changing the filters constantly was a big hassle, plus water flow was bad as everything got clogged up.

The plan was to gut everything and replace it with back flushing filters that wouldn't require as much maintenance, as well as correct for several issues: Acidity (6.5 pH), iron, and iron bacteria.

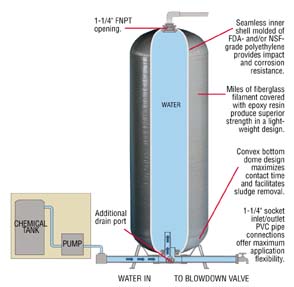

The new system is: Chlorine injection -> Pressure tank -> Contact tank -> Spin down filter -> pH Neutralizer -> Iron filter -> Carbon filter -> Ultra filter -> Secondary pressure tank -> service to house.

The last component is a Cascadian UltraFilter UF, put in place by the previous owner about 3 years ago. I tried to put everything in place as it was before - it has a solenoid valve on the input that shuts off water while it's back flushing, as it requires the second pressure tank for clean water back flush.

It seems like this valve is just not letting much water past it. It is listed as NO/normally open. I opened the valve and there is a diaphragm and o-ring that looks like it presses down into the valve body to shut off the water. After putting it back together now I get loud vibrations in the system when trying to flow water through it.

I was just wondering if anybody had any suggestions. I'm also contacting the company hoping they will be of help but thought I'd try here too just in case.

Any other thoughts/suggestions on dealing with a very dirty well are appreciated as well. I got all my new equipment from Clean Water Systems, and they seemed to think the three filters before the UF would clean the water enough for the UF to do its job. I'm just not sure right now. I did run a lot of water yesterday doing the initial back flush of all the filters and really put the well through its paces so I brought up a lot of silt.

I'm just a bit frazzled right now as I've worked on redoing all the plumbing for about 14 hrs/day for the last three days and still have no water .

.

Some small background first:

I guess the main issue is my well is a piece of crap - it is *very* silty, and if the pump is run continuously for say 10 minutes the water coming out looks like chocolate milk. The old system had a Harmsco unit with 7 canister filters inside, then a big blue, then an ultrafilter. Changing the filters constantly was a big hassle, plus water flow was bad as everything got clogged up.

The plan was to gut everything and replace it with back flushing filters that wouldn't require as much maintenance, as well as correct for several issues: Acidity (6.5 pH), iron, and iron bacteria.

The new system is: Chlorine injection -> Pressure tank -> Contact tank -> Spin down filter -> pH Neutralizer -> Iron filter -> Carbon filter -> Ultra filter -> Secondary pressure tank -> service to house.

The last component is a Cascadian UltraFilter UF, put in place by the previous owner about 3 years ago. I tried to put everything in place as it was before - it has a solenoid valve on the input that shuts off water while it's back flushing, as it requires the second pressure tank for clean water back flush.

It seems like this valve is just not letting much water past it. It is listed as NO/normally open. I opened the valve and there is a diaphragm and o-ring that looks like it presses down into the valve body to shut off the water. After putting it back together now I get loud vibrations in the system when trying to flow water through it.

I was just wondering if anybody had any suggestions. I'm also contacting the company hoping they will be of help but thought I'd try here too just in case.

Any other thoughts/suggestions on dealing with a very dirty well are appreciated as well. I got all my new equipment from Clean Water Systems, and they seemed to think the three filters before the UF would clean the water enough for the UF to do its job. I'm just not sure right now. I did run a lot of water yesterday doing the initial back flush of all the filters and really put the well through its paces so I brought up a lot of silt.

I'm just a bit frazzled right now as I've worked on redoing all the plumbing for about 14 hrs/day for the last three days and still have no water