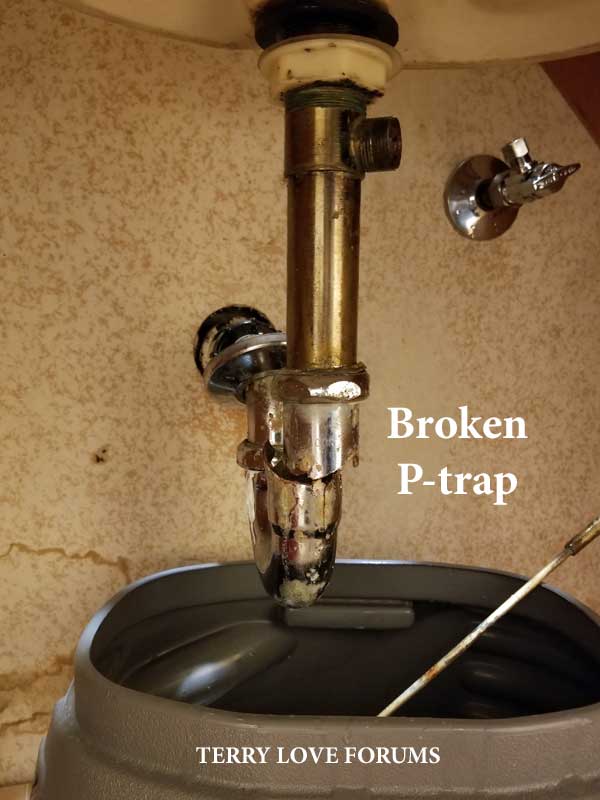

I had a leak under a laundry sink. The tail piece, P-trap and waste arm are chrome-plated. I had to apply a torch to the joints, but finally got the parts separated. The waste arm must have been the culprit as it crumbled where it was connected to the P-trap. The problem is that I can not remove the waste arm from the copper drain line. After applying penetrating oil and using the biggest wrench I could get back there, it dawned on me that the waste arm is likely soldered into to the copper drain line. Do I cut off the waste arm and use one of those rubber connectors (e.g., Fernco)? If so, do I leave some of the waste arm sticking out or cut it flush with the copper drain pipe?

Last edited by a moderator: