eastglacier

New Member

Hello all,

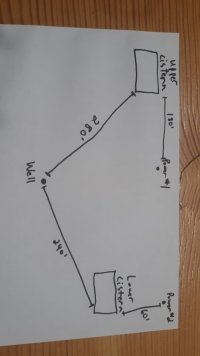

We currently have two cabins separated by about 400'. Each cabin has a 2500 gallon cistern that it is plumbed to. We have been getting by for 5 years hauling water and filling cisterns after we drilled a dry well. This past fall we dug a new low-producing well (1.5 gpm) that is about midway between the two cisterns. Each cistern has a float switch, but I can't seem to figure out the best way to fill them both with one well. Can somebody help me figure out our best option here? If it's helpful, one cistern is 40' vertical above the other.

Thanks for your time,

Nate

We currently have two cabins separated by about 400'. Each cabin has a 2500 gallon cistern that it is plumbed to. We have been getting by for 5 years hauling water and filling cisterns after we drilled a dry well. This past fall we dug a new low-producing well (1.5 gpm) that is about midway between the two cisterns. Each cistern has a float switch, but I can't seem to figure out the best way to fill them both with one well. Can somebody help me figure out our best option here? If it's helpful, one cistern is 40' vertical above the other.

Thanks for your time,

Nate