Djbrady105

New Member

Hi,

I joined this forum because while I was at work today, my wife informed me that water pressure was terrible in the entire house. When I got home, I did troubleshooting. I immediately see that the pump double breaker is tripped. I reset it, hear a growling noise for about half a second, and the breaker trips again. In a few I try again. a millisecond of noise then nothing. I open the main cutoff switch that is after the breaker, and 246 volt registers coming in. Nothing out to pressure switch. I test the 2 large cylinder fuses, and the one on the hot leg is blown. I'm figuring this indicates a seized pump. So no water at all for the house/family. I'd like to save money and possibly do this myself. I'm not a plumbing pro, but very handy, determined, and teachable. I did teach myself to do all the inside plumbing repairs, and soldering copper pipes.

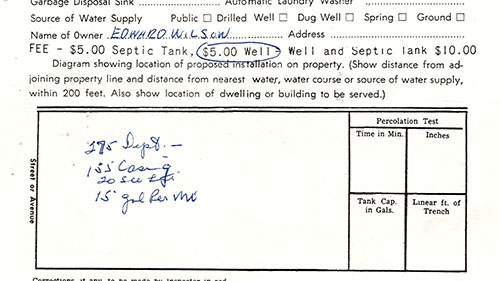

I'm overwhelmed with new terminology, and that is making it difficult to know what to buy. Please help me to know what pump to get. If I do this myself, I can afford to invest in a better pump. I don't want to go through this again in the near future. I know it involves a bunch of factors. I've included a picture of the info from the Franklin control box, which shows a 3 wire pump. I called the town building dept, and they sent me the only thing they have on file, which is the well permit request from 1972. I'm including a screenshot of the minimal info. Thank you all very much.

I joined this forum because while I was at work today, my wife informed me that water pressure was terrible in the entire house. When I got home, I did troubleshooting. I immediately see that the pump double breaker is tripped. I reset it, hear a growling noise for about half a second, and the breaker trips again. In a few I try again. a millisecond of noise then nothing. I open the main cutoff switch that is after the breaker, and 246 volt registers coming in. Nothing out to pressure switch. I test the 2 large cylinder fuses, and the one on the hot leg is blown. I'm figuring this indicates a seized pump. So no water at all for the house/family. I'd like to save money and possibly do this myself. I'm not a plumbing pro, but very handy, determined, and teachable. I did teach myself to do all the inside plumbing repairs, and soldering copper pipes.

I'm overwhelmed with new terminology, and that is making it difficult to know what to buy. Please help me to know what pump to get. If I do this myself, I can afford to invest in a better pump. I don't want to go through this again in the near future. I know it involves a bunch of factors. I've included a picture of the info from the Franklin control box, which shows a 3 wire pump. I called the town building dept, and they sent me the only thing they have on file, which is the well permit request from 1972. I'm including a screenshot of the minimal info. Thank you all very much.