OklahomaDave

New Member

Hi all..

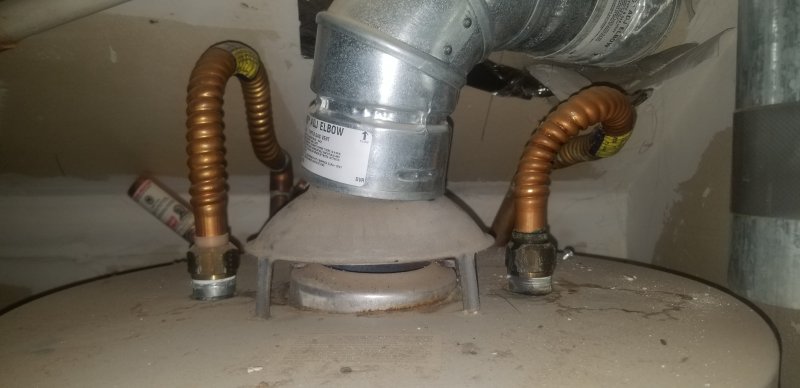

I am getting ready to replace our original, 20-year-old Bradford White water heater. The installer hooked it up during construction to the house water with copper flex lines, and I have heard differing opinions on whether it's a good idea to reuse them on the new tank. I am planning to move from this 40-gal variety to a short 50-gal, which will probably be at least two inches shorter if not more.

My first instinct is to replace them with SS flexible connections, but if this is a dumb/unnecessary idea, it's better to know now! Thanks.

I am getting ready to replace our original, 20-year-old Bradford White water heater. The installer hooked it up during construction to the house water with copper flex lines, and I have heard differing opinions on whether it's a good idea to reuse them on the new tank. I am planning to move from this 40-gal variety to a short 50-gal, which will probably be at least two inches shorter if not more.

My first instinct is to replace them with SS flexible connections, but if this is a dumb/unnecessary idea, it's better to know now! Thanks.

Last edited by a moderator: