Claraarcher

Member

Hi Again,

another question if you please. If i go the route of opening the ceiling i think that will work out so long as inspectors says ok.

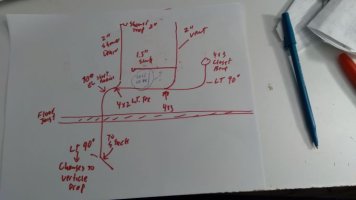

Thinking about the waste lines i am curious if i can use one 2" vent for the toilet and vanity as shown in Red or should i use a separate tee connection to the 3" waste with separate 1.5 vent line tied into the 2" vent line that i drew in blue on the attached?

thanks again!!

edit - i think i mixed up the last two 90s - the one to the stack (horizontal to vertical) should be a short radius and the one that goes through the joist (horizontal to horizontal) should be a long radius.

another question if you please. If i go the route of opening the ceiling i think that will work out so long as inspectors says ok.

Thinking about the waste lines i am curious if i can use one 2" vent for the toilet and vanity as shown in Red or should i use a separate tee connection to the 3" waste with separate 1.5 vent line tied into the 2" vent line that i drew in blue on the attached?

thanks again!!

edit - i think i mixed up the last two 90s - the one to the stack (horizontal to vertical) should be a short radius and the one that goes through the joist (horizontal to horizontal) should be a long radius.

Attachments

Last edited: