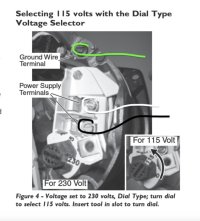

Just a review from the owners manual for the pump. Be sure you moved the dial to 115v setting. The power leads can be either way. The manual also includes a wire size chart. For your needs a 10 AWG is recommended, though with 12 gauge it should have worked without a load on the impeller. At 19.9 amps running under load, a 30 amp with 10 AWG wire is needed.

Was there an 115v old pump that you replaced? An old fuse panel can have 240 volts. I would remove the cover of the fuse panel and verify the wiring is good and do check that you have ~115v and at the motor. If the motor is toast and you cannot rewire for 240v, get the 1 HP motor. According to the manual, 1HP motor is also wired for 240v. At one time for irrigation pumps, 1HP pumps were 115v and 240v was not an option.

At the motor with the cover off and power disconnect or switched off, you should be able to get a finger on the centrifugal switch and shaft and be able to spin the shaft motor to be sure that the motor is not seized. Check the wiring for burns or melted insulation going to the start capacitor and centrifugal switch.

What the Valveman described maybe true since all motors have a locked rotor rating. With the correct voltage, and the motor seize (locked) it will draw current, the motor will get hot but it should not burn as in fire and not necessarily trip a breaker or fuse. This is a UL requirement. Pool and irrigation pumps use the same motors. One time my pool pump lockup and only noticed it when the pool water didn't look right, it could have been locked up for a week and the motor was hot enough to make toast but never tripped the 240v breaker.

View attachment 85904View attachment 85906