Djc11369

New Member

Hi all,

My pump of 23 years is showing signs of it's age, it used to fill my 20 gal tank in about 30-40 seconds and now takes about 1 minute and 45 seconds. It's supposed to have a 6.2 gal drawdown so I'd say it's outputting about 3.5 gpm? It's not adequate to backwash my iron filter or water softener, they used to sound like a jet engine taking off and now I don't hear them much at all except maybe a minute or two.

I've also been experiencing random puffs of air from different fixtures, it's not sputtering but just a quick puff and isn't very frequent so I'm hoping that it's tied to the pump as well. Tank was replaced 2 years ago, I just double checked the precharge a month ago and it was down 1 psi so topped off and good there.

I wasn't provided any detail on my well when it was drilled other than verbally that it's 60 feet deep. No info on current pump, I've discerned that my setup is 2 wire and 230V. Pressure switch is set at 30/50 although I am considering adjusting and going to 40/60.

What I've been able to collect for info: 1" poly pipe, 87 feet from well to house, static water level 19 feet, 6" casing. I tried to get measure how much it draws down when the pump is running but I stop at something at about 29 feet, I believe it's a plastic cable guide but not positive. There is one above that I had to finesse by line through. I think I see glimmer of water just below it.

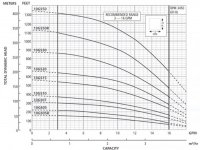

So with all that said, and please correct me if I'm wrong because I probably am, I calculate a TDH@50 psi of 185 feet (209 feet @ 60 psi). I assumed 60 feet for elevation head because I have no idea how far down the pump really is, ~9 feet for friction head and 116 (or 140) feet for pressure head.

Only 2 people in the 3 bedroom, 2 bath house but only 1 shower is used at any given time along with maybe a sink or toilet flush. Maybe a dishwasher or washing machine running. If you use the 1 gpm per fixture count method it'd be 10 gpm.

Sorry for the long post, I'm sure I forgot something. Any input on an appropriate pump would be appreciated, Gould seems to be what's common in my neck of the woods but Grundfos or...?

My pump of 23 years is showing signs of it's age, it used to fill my 20 gal tank in about 30-40 seconds and now takes about 1 minute and 45 seconds. It's supposed to have a 6.2 gal drawdown so I'd say it's outputting about 3.5 gpm? It's not adequate to backwash my iron filter or water softener, they used to sound like a jet engine taking off and now I don't hear them much at all except maybe a minute or two.

I've also been experiencing random puffs of air from different fixtures, it's not sputtering but just a quick puff and isn't very frequent so I'm hoping that it's tied to the pump as well. Tank was replaced 2 years ago, I just double checked the precharge a month ago and it was down 1 psi so topped off and good there.

I wasn't provided any detail on my well when it was drilled other than verbally that it's 60 feet deep. No info on current pump, I've discerned that my setup is 2 wire and 230V. Pressure switch is set at 30/50 although I am considering adjusting and going to 40/60.

What I've been able to collect for info: 1" poly pipe, 87 feet from well to house, static water level 19 feet, 6" casing. I tried to get measure how much it draws down when the pump is running but I stop at something at about 29 feet, I believe it's a plastic cable guide but not positive. There is one above that I had to finesse by line through. I think I see glimmer of water just below it.

So with all that said, and please correct me if I'm wrong because I probably am, I calculate a TDH@50 psi of 185 feet (209 feet @ 60 psi). I assumed 60 feet for elevation head because I have no idea how far down the pump really is, ~9 feet for friction head and 116 (or 140) feet for pressure head.

Only 2 people in the 3 bedroom, 2 bath house but only 1 shower is used at any given time along with maybe a sink or toilet flush. Maybe a dishwasher or washing machine running. If you use the 1 gpm per fixture count method it'd be 10 gpm.

Sorry for the long post, I'm sure I forgot something. Any input on an appropriate pump would be appreciated, Gould seems to be what's common in my neck of the woods but Grundfos or...?