The heat load of a house with those specs is likely to be around/under 15,000 BTU/hr at your

99%outside design temp of about +5F (the design temp for nearby Mt. Vernon IL), which makes just about all 2 stage gas furnaces (except maybe a smaller

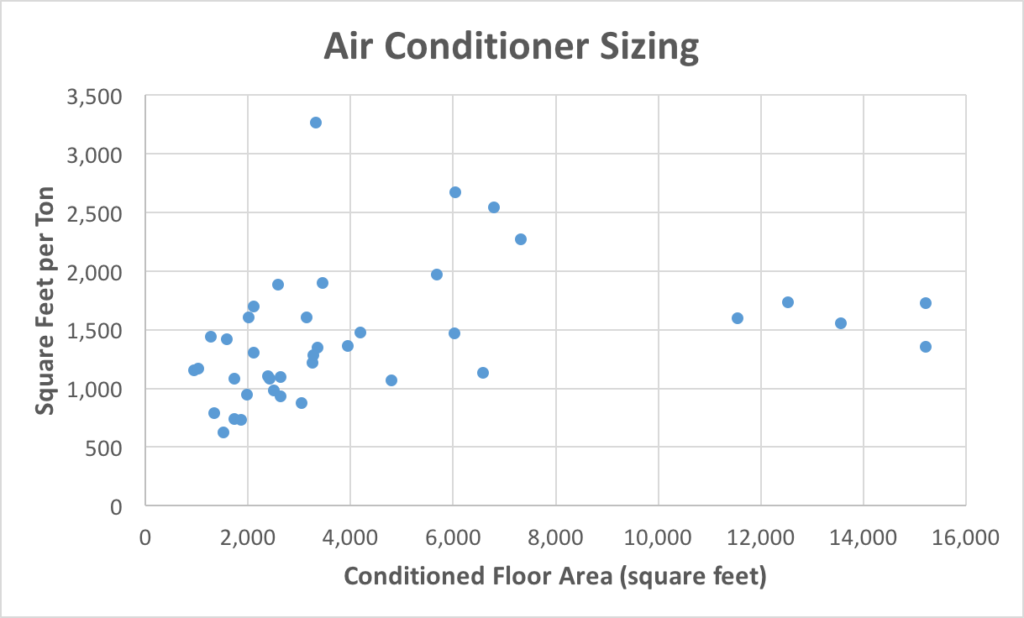

Dettson Chinook) 2x oversized even at low-fire. The cooling load is probably about 1 ton, 1.25 tons at most.

Is there any sub-slab insulation in the basement, or is it just the walls?

The smart thing to do would be to have a competent engineer or RESNET rater run an AGGRESSIVE (per the Manual) room-by-room Manual-J load calculation on the place.

The first floor can almost certainly be heated and cooled with a fully modulating 1.5 ton

Fujitsu 18RLFCD ducted mini-split heat pump. There are other heat pump options that can work almost as well, but most won't be as comfortable as the fully modulating Fujitsu, which can throttle back to 3100 BTU/hr @ 47F, but still delivers over 20,000 BTU/hr @ +17F. (You'd have to consult the extended temperature capacity tables to determine the capacity at +5F, but it's almost certainly going to be enough.)

A 2-ton

Carrier Infinity w/Greenspeed would also cover your load. (Click on the "Heating Capacity" tab, and select the 24VNA024A, in the lower left corner pull down, then try a few different air handler options.) It modulates with a 2.5:1 turn down ratio (drops back to 40% of max capacity), and still delivers ~20,000 BTU/hr @ +5F. It's usually quite a bit more expensive than the 1.5 ton Fujitsu though, and not nearly the same modulation range, but it can drop to under 10,000 BTU/hr when the cooling loads are low. The 1.5 ton Fujitsu would deliver higher comfort since it would run nearly continuously rather than cycling, even in the shoulder seasons when the loads are much lower, since it's minimum modulation is 3100 BTU/hr in both heating and cooling modes.

The heat loss characteristics of basements are very different from those of the first floor. With the upstairs air-conditioned the only cooling load in the basement will be latent (humidity), so if the main return for the ducted AC takes in basement air, the dry air from upstairs would take care of it. Heating the basement could be a small hydronic (pumped hot water) loop running off the water heater.

An alternative solution to a heat pump would be an air hander with the right sized cooling coil (probably 1.5 tons or smaller) and a hydronic heating coil running off a condensing water heater.

FirstCo has a number air handlers to choose from that would fill the bill. Something like the

24CLX-HW can work with a 1.5 ton condenser, and delivers ~25,000 BTU/hr at an entering water temperature of 130F, and would cover your load even with 120F water. That might actually be oversized, but there are dozens of other models- the

18HBQBR might be a better fit for your loads, but until somebody runs the numbers it's hard to be too specific.

If you want to take a stab at your own load calculations,

loadcalc is easy to use for a quick & dirty first-cut estimate. It regularly oversizes things, so be sure to select for maximum air-tightness and be a bit aggressive on the window specs, etc. Even then it's likely to deliver numbers 15-25% bigger than a more rigorous & aggressive Manual-J using professional tools.