Thanks for the engineering check and thoughts on this Wayne!! Some notes and data, below.

Reach, the sources of water running are a across a number of diverse sources, combined. More information than probably desired, but listed those below for the idea. I could get 5GPM pressure for the laundry sink at the irrigation manifold and yard hydrant, as well.

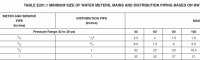

Know that the main distribution line in the home is 3/4" (why I thought going to 1" was going to be sufficient) - so I included in my test some combined runs with some (normally 10.2 GPM) irrigation running outside, and the fixtures running inside. Also, 2 outside zones running concurrently (that didn't irrigate very well!). In most instances, I took pressure readings at at least 2 locations (hose bib that feeds off the interior, irrigation manifold before the supply enters the home, and at the yard hydrant). You all probably gathered already, but the volumes are not coming from the same location the pressure was taken, and the front hose bib, feeds from the inside of the house.

I have 2 additional readings for the yard hydrant, alone -- which I didn't include in the below chart, but are relevant.

Yard Hydrant - 19.8 GPM. Pressure at house hose bib: 5 psi. Pressure at Irrigation manifold: 16 psi.

The distances... Yard Hydrant to Meter pit should be pretty good (though does not account for the 6' rise to the outlet of the yard hydrant), and the edge of the residential street to the meter pit is about 17', with the lines entering the pit about 4.5' underground (I am guessing the main may be deeper). Yard hydrant to irrigation was measured in the air, but could vary some, as I don't t know the exact path, and (more importantly, it dives under a 7' deep, 15' wide ditch, so I made some assumptions there... definitely not exact).

Yes, it is a 3/4" meter, but the utility said it would have a 3/4" line coming into it, so that means if upgrade is every necessary, cost should be much lower. It is a relatively new meter, and if needed I can get the model number.

I'll see if I can chart out the flow versus pressure drop, though again - numbers are probably +/- 1.5 psi, based on the duration of the test (though in most instances I didn't see variance). Yes, I was wondering about the diverging nature of the green and other lines. Very, very interesting comments on the first section possibly being the constriction. I wonder if that bend leaving the meter pit, where it looks like the pipe went more oval is the culprit.

I would say that my methodology had some room for error (esp, given the below), and I had an outlier or two that I scratched my head on, then omitted from the plot (red triangles, below). Here are a few potential sources of inaccuracy:

- Biggest error is likely around the reading of flow at the meter. I took 10s readings, and those .xx digital numbers are moving real fast at 10+gpm... higher flows could easily have varied 0.5-1GPM.

- These tests too quite some time to test, and during that time, there was a little variance in static pressure... I think +/- 1.5 psi. Having only one gauge, the pressures were taken in groupings at a given pressure point, not running around the yard for each one.

- At the start of the test, the pressure would drop low, then come back up (e.g. drops from 60 -> 35, then stabilizes at 42)

- I always had to let the test run for maybe 30 seconds, then relieve some pressure from the gauge via schrader valve, or it would read too high (still digesting that).

- Now that we have the big picture, if a more accurate/precise test needs to be re-run, I could do that.

All this said, ultimately I'll be plumbing the inside, and having to come back in resolve this after the remodel, but it is good get an idea now of what may be going on (which is largely, probably the undersized supply pipe).