You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Navien wall hung boiler question

- Thread starter Plumber69

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

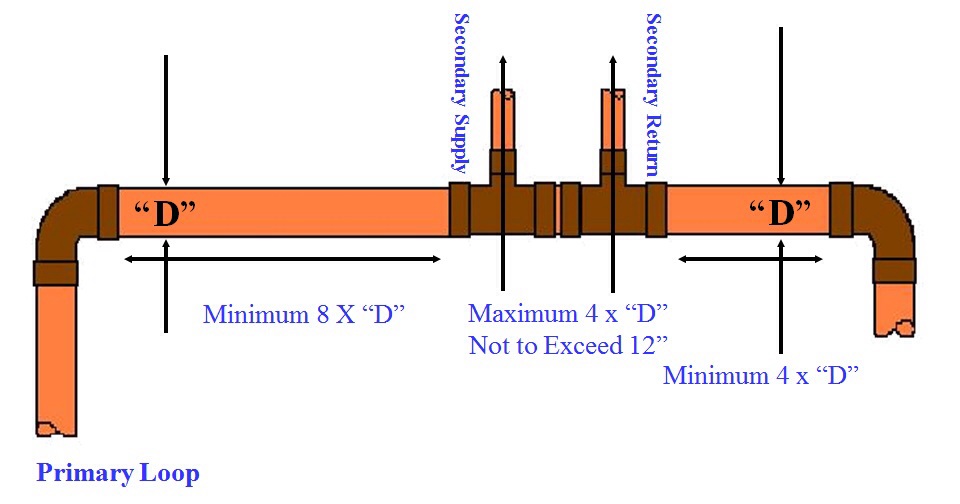

The pumping head of the heat exchanger in the Navien is much higher than a cast iron boiler- you may or may not be able to push enough flow through that HX to support what the radiation needs. If you have the software or are really good with a paper & pencil it's possible to figure out what's needed and what's possible and spec the pump, but if you're not sure it's easier to just plumb it primary/secondary with a hydraulic separator (such as the pre-engineered manifold).

You can make your own hydraulic separator out of fittings using closely spaced tees, but the tees have to be spaced very closely to achieve adequate separation between the primary (boiler loop) and secondary (radiation loop) flows.

How much radiation, is there on this system, and which model Navien? It's pretty common to see these condensing boilers hooked up to systems that don't have enough radiation to run the boiler in condensing mode without short-cycling. See this bit o' bloggery for the napkin math on that.

You can make your own hydraulic separator out of fittings using closely spaced tees, but the tees have to be spaced very closely to achieve adequate separation between the primary (boiler loop) and secondary (radiation loop) flows.

How much radiation, is there on this system, and which model Navien? It's pretty common to see these condensing boilers hooked up to systems that don't have enough radiation to run the boiler in condensing mode without short-cycling. See this bit o' bloggery for the napkin math on that.

Sponsor

Paid Advertisement

Plumber69

In the Trades

It's a NHB110 it's only heating 8 baseboards on one floor. Not a very big house. Some manifolds show the pump right on the return of the boiler. I'm confused with the manifold setup. I would think the hot water would just circulate thru the manifold and not the system if the pump was right on the ruturn. If the pump was on the send I would think it would just pump right thru the manifold

When plumbing primary/secondary there are separate pumps for the primary & secondary loops, depending on what the flow requirements are. This document lists some appropriate (for this boiler series) pumps for the primary loop (the boiler loop) on page 20 (p21, in PDF.) The Taco 007e high efficiency pump would use 1/4 the power of any of those listed.

The eight baseboards could be 20' long each or, 2' long, or anything in between. The number of baseboards isn't important- the total baseboard (not plumbing, just the fin -tube sections) is. So you have at least 16' of baseboard- hopefully it's a lot more than that. This boiler is oversized for 95% of the houses in the Canada, and bigger is not better.

Did you read the sizing condensing boilers blog article?

At Prince Rupert's -11C/+13F 99% outside design temp a typical 2x4/R13 house with clear glass double panes would have a heat load to floor area ratio of about 12 BTU/hr per square foot give or take a few. (Yes, I know it gets a lot colder than -11C sometimes, but it's only for 87 hours in a typical year, and not consecutive hours.) So a modestly sized 1500' house would have a likely heat load of ~15-22,000 BTU/hr @ -11C, and maybe as much 30,000 BTU/hr @ -20C. At high fire- high temperature, well out of the condensing temperature zone the NHB delivers about 95,000 BTU/hr, which makes it about 4x oversized for the likely design load, and 3x oversized for the coldest few hours of the year (or a 1500' house.) If you're expecting a cold snap to hit -100C (not happening, even during the next ice age) it would be about right, assuming you even had enough baseboard to emit the 95KBTU/hr.

At min-fire output of the NHB-110 in condensing mode is about 9500 BTU/hr . To run at 95% efficiency takes an average water temp of 110F or lower, at which point typical fin-tube baseboard is putting out about 150 BTU/hr per running foot, 200 tops. So to deliver the full 9500 BTU/hr without cycling takes between 50-65 feet of baseboard.

If you don't have at least 5o' of baseboard on the loop, downsizing to the NHB-055 or NHB-080 would be better. Those can modulate down to 7,600 BTU/hr out, and can operate in condensing mode with~40-45' of baseboard.

If there is less than 30' of baseboard it will have to operate above the condensing range to avoid short-cycling into low efficiency or an early grave.

The eight baseboards could be 20' long each or, 2' long, or anything in between. The number of baseboards isn't important- the total baseboard (not plumbing, just the fin -tube sections) is. So you have at least 16' of baseboard- hopefully it's a lot more than that. This boiler is oversized for 95% of the houses in the Canada, and bigger is not better.

Did you read the sizing condensing boilers blog article?

At Prince Rupert's -11C/+13F 99% outside design temp a typical 2x4/R13 house with clear glass double panes would have a heat load to floor area ratio of about 12 BTU/hr per square foot give or take a few. (Yes, I know it gets a lot colder than -11C sometimes, but it's only for 87 hours in a typical year, and not consecutive hours.) So a modestly sized 1500' house would have a likely heat load of ~15-22,000 BTU/hr @ -11C, and maybe as much 30,000 BTU/hr @ -20C. At high fire- high temperature, well out of the condensing temperature zone the NHB delivers about 95,000 BTU/hr, which makes it about 4x oversized for the likely design load, and 3x oversized for the coldest few hours of the year (or a 1500' house.) If you're expecting a cold snap to hit -100C (not happening, even during the next ice age) it would be about right, assuming you even had enough baseboard to emit the 95KBTU/hr.

At min-fire output of the NHB-110 in condensing mode is about 9500 BTU/hr . To run at 95% efficiency takes an average water temp of 110F or lower, at which point typical fin-tube baseboard is putting out about 150 BTU/hr per running foot, 200 tops. So to deliver the full 9500 BTU/hr without cycling takes between 50-65 feet of baseboard.

If you don't have at least 5o' of baseboard on the loop, downsizing to the NHB-055 or NHB-080 would be better. Those can modulate down to 7,600 BTU/hr out, and can operate in condensing mode with~40-45' of baseboard.

If there is less than 30' of baseboard it will have to operate above the condensing range to avoid short-cycling into low efficiency or an early grave.

Plumber69

In the Trades

There is 50 feet baseboard. On a one pipe system I still need two pumps?

Plumber69

In the Trades

I was really looking for more if a simple answer. The btu is correct for the house. Why 2 pumps would be needed still doesn't answer my question

Plumber69

In the Trades

It's a one pipe systemI was really looking for more if a simple answer. The btu is correct for the house. Why 2 pumps would be needed still doesn't answer my question

Michael Young

In the Trades

ok. you want to keep it simple. So when it doubt... JUST freakin’ TRY IT!!! If it gets the job done, then yeah. you can do it. JUST freakin’ TRY ITI'm replacing a boiler with a navien on a one pipe system. But it's showing this manifold setup. Do I need this installed? Can I not just tie the return in the return. Supply in the supply. Of course unions valves expansion tank ect...

Michael Young

In the Trades

OMG, Terry is using software to edit my use of the word "Gosh darn golly", shit, cunt

Michael Young

In the Trades

OMG, Terry is using software to edit my use of the word "Gosh darn golly", shit, cunt

hah, it's just a FVck filterOMG, Terry is using software to edit my use of the word "Gosh darn golly", shit, cunt

I was really looking for more if a simple answer. The btu is correct for the house. Why 2 pumps would be needed still doesn't answer my question

Yes the system is a one pipe system.

No the BTU is not correct for anything that would described as "Not a very big house", and probably not for the amount of radiation either, but it can probably be made to work TBD. (I live in modestly insulated 2x4 framed 2400' house with 1600' of insulated basement. That boiler could keep my house at 20C indoors at an outdoor temperature of -110C.)

The heat exchanger on the Navien is many times more restrictive than that of a cast iron boiler, exerting a lot of back pressure. The plumbing to the baseboard is also restrictive creating a lot of back pressure. (How much, we don't know without a lot more information about your system.) If the combined impedence of the radiation plumbing + heat exchanger is too much, there sufficient flow through the Navien, the in to out temperature difference at the boiler may exceed it's operating specs, could cause flash-boil which lowers the heat exchange efficiency (and can be pretty noisy) and can even damage the boiler. By setting it up as two intersecting loops and two pumps the minimum flow through the boiler is guaranteed.

Hydronic heating is more than just a plumbing project, and the analysis I've been suggesting isn't the hard-math version. If you're not willing to take the measurements and do some 5th grade arithmetic on the system there really no way to tell if it's going to work pumped direct or not.

Some simple math worth running:

At the NHB-110's maximum output temp of 180F and a fairly high flow rate through the baseboard the most you'll be able to get out of the baseboard is about 500 BTU/hr per running foot. In order to emit the full output of the thing at high fire then takes about 100,000/500= 200 feet of baseboard.

Do you even have 200' of baseboard? (I'm guessing not.)

To deliver the full output of the NHB-055 at high fire takes about 100' of baseboard, which you might actually have. With the NHB-080 it takes about 150'.

With only 100' of baseboard or less you can't heat into the house any faster or better with the NHB-110 than you do with the NHB-055 or NHB-080, but the -110 will do a lot more cycling on/off (at any water temperature.)

At the NHB-110's maximum output temp of 180F and a fairly high flow rate through the baseboard the most you'll be able to get out of the baseboard is about 500 BTU/hr per running foot. In order to emit the full output of the thing at high fire then takes about 100,000/500= 200 feet of baseboard.

Do you even have 200' of baseboard? (I'm guessing not.)

To deliver the full output of the NHB-055 at high fire takes about 100' of baseboard, which you might actually have. With the NHB-080 it takes about 150'.

With only 100' of baseboard or less you can't heat into the house any faster or better with the NHB-110 than you do with the NHB-055 or NHB-080, but the -110 will do a lot more cycling on/off (at any water temperature.)

Plumber69

In the Trades

There is approximately 90 feet of baseboard each taken off a 1 11/4" header

90' x ~500 BTU/hr per foot = ~45,000 BTU/hr.

That's the most heat your radiation can deliver at the maximum temperature settings for this series. Seems like the NHB-055 is a good fit. The extra 50K of burner for the -110 buys nothing. But with 90' of baseboard operated as a single zone you'll still be OK with the -110:

90' x 200 BTU/hr- 18,000 BTU/hr.

That means you have enough radiation to run the NHB-110 in a condensing mode without excess cycling, since it can dial back to about half-that at low fire. (If you've already purchased the -110, there is no need to return it and incur restocking charges, etc.)

Calculating the pumping head of your radiation takes more complicated math, and a better description/measurement of all the pipe diameters, lengths, fittings, etc. Hydronic design software makes it easier to spec the pump, if pumping direct through a high pumping-head boiler, which is why it's safer to plumb it primary/secondary using closely spaced tees as the hydraulic seperator, and us a high efficiency pump (eg Taco -007e ) for the boiler loop.

That's the most heat your radiation can deliver at the maximum temperature settings for this series. Seems like the NHB-055 is a good fit. The extra 50K of burner for the -110 buys nothing. But with 90' of baseboard operated as a single zone you'll still be OK with the -110:

90' x 200 BTU/hr- 18,000 BTU/hr.

That means you have enough radiation to run the NHB-110 in a condensing mode without excess cycling, since it can dial back to about half-that at low fire. (If you've already purchased the -110, there is no need to return it and incur restocking charges, etc.)

Calculating the pumping head of your radiation takes more complicated math, and a better description/measurement of all the pipe diameters, lengths, fittings, etc. Hydronic design software makes it easier to spec the pump, if pumping direct through a high pumping-head boiler, which is why it's safer to plumb it primary/secondary using closely spaced tees as the hydraulic seperator, and us a high efficiency pump (eg Taco -007e ) for the boiler loop.

Plumber69

In the Trades

Thanks for your help. When the unit was bought there was intention of running another 80 feet on another floor. This got cancelled. So what I gather is it is better to have a pump on the return with the loop. And another pump on the send after the air scoop expansion tank setup

Plumber69

In the Trades

90' x ~500 BTU/hr per foot = ~45,000 BTU/hr.

I plumbed it in primary and secondary with to pumps. Exactly the way shown in book. You say I have to dial it back? Is that easy

That's the most heat your radiation can deliver at the maximum temperature settings for this series. Seems like the NHB-055 is a good fit. The extra 50K of burner for the -110 buys nothing. But with 90' of baseboard operated as a single zone you'll still be OK with the -110:

90' x 200 BTU/hr- 18,000 BTU/hr.

That means you have enough radiation to run the NHB-110 in a condensing mode without excess cycling, since it can dial back to about half-that at low fire. (If you've already purchased the -110, there is no need to return it and incur restocking charges, etc.)

Calculating the pumping head of your radiation takes more complicated math, and a better description/measurement of all the pipe diameters, lengths, fittings, etc. Hydronic design software makes it easier to spec the pump, if pumping direct through a high pumping-head boiler, which is why it's safer to plumb it primary/secondary using closely spaced tees as the hydraulic seperator, and us a high efficiency pump (eg Taco -007e ) for the boiler loop.

Michael Young

In the Trades

You'll be fine without the second pumpThanks for your help. When the unit was bought there was intention of running another 80 feet on another floor. This got cancelled. So what I gather is it is better to have a pump on the return with the loop. And another pump on the send after the air scoop expansion tank setup

Plumber69

In the Trades

I called navien tech they said 2 pumps is mandatoryYou'll be fine without the second pump

Plumber69

In the Trades

Unless I ditched the whole manifold setup one pump wouldn't workI called navien tech they said 2 pumps is mandatory

One pump MIGHT work if specified properly, but there's nothing in the description that says it'll obviously work with a single pump that has a Taco-007 type pump curve.

But if Navien voids the warranty running it single-pump you'd better be dead-sure the math is right before running it that way. If the heat exchanger fails because it's been chronically operating out of spec on min/max flow rates or max delta-T it becomes your problem.

But if Navien voids the warranty running it single-pump you'd better be dead-sure the math is right before running it that way. If the heat exchanger fails because it's been chronically operating out of spec on min/max flow rates or max delta-T it becomes your problem.

Similar threads

- Replies

- 0

- Views

- 139

- Replies

- 0

- Views

- 166

- Replies

- 0

- Views

- 133

- Replies

- 0

- Views

- 142

- Replies

- 8

- Views

- 422