steve agnew

...just a little more voltage please...

Just installed a Navien 240S, 199,900 Btu/s hr, enough for 3 simultaneous showers...or so it would seem. There is a lot more to on-demand hot water that the brochures do not mention at all, but the technology is great anyway.

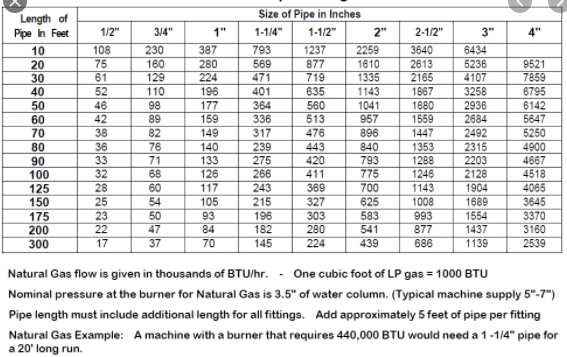

First of all, if you put in a big unit like the 240s, make sure that you have enough natural gas line capacity. Turns out, in my bedroom wing, the line was 280' of 1-1/4" black pipe, which includes many elbows at 5' per elbow. Thus, this run only allows 150,000 btus/hr...by the table and I wish that the Navien brochure had said something about this. Here is the piping chart...

However, there are online calcs for pressure drop and those only showed about 1" drop for 200 kBTU/hr. I had to neck the flow down to 3.2 gpm and two showers by turning the supply valve down to the unit...seems silly, but it works...

A call to Joe at Navien technical support assured me that what I was measuring was impossible unless the gas inlet was plugged somehow...a brand new unit and a brand new 3/4" flexible line...a plug didn't seem likely, but Joe was right. The Ace Hardware 3/4" line came with fittings that had flow limits of 165 kBtu/hr, and I simply did not read the fine print. Replacing this stupid flow limit corrected the problem and now I have 120 F at 6.0 gpm and no sandwiching at all.

Finally, of course, the sandwich effect of cycling hot and cold, which is a common feature of all on demand hot water, even electric. So...there should also just be a parameter to set, right? To adjust the time constant right? This would normally be an easy thing, but instead, Navien not only does not inform you of the inevitablity of sandwiching with low gas pressure, but your contractor's solution means more money for recirculation with a tank or a loop. So much for efficiency...My suggestion is simply to go slow at first to warm the unit up and then let 'er rip...

Honestly, this is even sillier because all you need to do is to start the flow low, wait for it to get hot, increase the flow again, and then do your shower. In other words...all it takes is a few extra minutes of time and wasted water...which is a lot cheaper than gas. But if you do not have the gas pressure, these two effects pile on each other and it took me a week to figure them out. Also had to buy a manometer to measure the natural gas pressure at the street and at the Navien. It turns out that I really have plenty of gas pressure, 6-10 in.w.c and my 280' 1-1/4" pipe run only drops about 1" w.c. at 200,000 btus/hr.

Now I'm glad I bought the 240s, but there would still be the sandwich problem if the gas flow is drops...so far, there has not been a problem. I have two gas furnaces at 80 kBtus/hr each, a gas stove, and a pool heater at 300 kBtus/hr, but no issues so far...very pleased...

Once I removed the flow restrictor that I had inadvertently installed, it was necessary to adjust the MIN1 gas pressure for the minimum fire for a flow. The spec was -0.02 to +0.30 w.c., but my pressure always fluctuated between -0.02 and +0.10, so I put the manometer on average and set the gas pressure best I could. Until the MIN1 gas pressure was set correctly, there was some sandwiching that occurred as noted above. Now all is well...so sandwiching at all...

Also, the high gas pressure at the Navien regulator was still just 3.5" wc that dropped to 2.0" wc when full flame even though the line outside the regulator was 7.5" wc at the unit that drops to just 6.5" when unit is full on. There is no problem and the 240s runs great even though the spec sheet says it should not run at these gas pressures. It now fills an 80 gallon whirlpool bath in just 8 mins...

First of all, if you put in a big unit like the 240s, make sure that you have enough natural gas line capacity. Turns out, in my bedroom wing, the line was 280' of 1-1/4" black pipe, which includes many elbows at 5' per elbow. Thus, this run only allows 150,000 btus/hr...by the table and I wish that the Navien brochure had said something about this. Here is the piping chart...

However, there are online calcs for pressure drop and those only showed about 1" drop for 200 kBTU/hr. I had to neck the flow down to 3.2 gpm and two showers by turning the supply valve down to the unit...seems silly, but it works...

A call to Joe at Navien technical support assured me that what I was measuring was impossible unless the gas inlet was plugged somehow...a brand new unit and a brand new 3/4" flexible line...a plug didn't seem likely, but Joe was right. The Ace Hardware 3/4" line came with fittings that had flow limits of 165 kBtu/hr, and I simply did not read the fine print. Replacing this stupid flow limit corrected the problem and now I have 120 F at 6.0 gpm and no sandwiching at all.

Finally, of course, the sandwich effect of cycling hot and cold, which is a common feature of all on demand hot water, even electric. So...there should also just be a parameter to set, right? To adjust the time constant right? This would normally be an easy thing, but instead, Navien not only does not inform you of the inevitablity of sandwiching with low gas pressure, but your contractor's solution means more money for recirculation with a tank or a loop. So much for efficiency...My suggestion is simply to go slow at first to warm the unit up and then let 'er rip...

Honestly, this is even sillier because all you need to do is to start the flow low, wait for it to get hot, increase the flow again, and then do your shower. In other words...all it takes is a few extra minutes of time and wasted water...which is a lot cheaper than gas. But if you do not have the gas pressure, these two effects pile on each other and it took me a week to figure them out. Also had to buy a manometer to measure the natural gas pressure at the street and at the Navien. It turns out that I really have plenty of gas pressure, 6-10 in.w.c and my 280' 1-1/4" pipe run only drops about 1" w.c. at 200,000 btus/hr.

Now I'm glad I bought the 240s, but there would still be the sandwich problem if the gas flow is drops...so far, there has not been a problem. I have two gas furnaces at 80 kBtus/hr each, a gas stove, and a pool heater at 300 kBtus/hr, but no issues so far...very pleased...

Once I removed the flow restrictor that I had inadvertently installed, it was necessary to adjust the MIN1 gas pressure for the minimum fire for a flow. The spec was -0.02 to +0.30 w.c., but my pressure always fluctuated between -0.02 and +0.10, so I put the manometer on average and set the gas pressure best I could. Until the MIN1 gas pressure was set correctly, there was some sandwiching that occurred as noted above. Now all is well...so sandwiching at all...

Also, the high gas pressure at the Navien regulator was still just 3.5" wc that dropped to 2.0" wc when full flame even though the line outside the regulator was 7.5" wc at the unit that drops to just 6.5" when unit is full on. There is no problem and the 240s runs great even though the spec sheet says it should not run at these gas pressures. It now fills an 80 gallon whirlpool bath in just 8 mins...

Last edited: