Gree is the largest air conditioning equipment manufacturer in China, and make equipment under contract for many other brands. (A number of second & third tier vendors' units are rebadged Gree units. I believe Carrier's mini-splits are all Gree designs.) Even

the big orange box store sells Gree mini-splits.

Saying that it doesn't need to be bigger than 9000 BTU doesn't really say what the loads really are, and it matters. Most manufacturers don't make mini-splits smaller than 9000 BTU, and your actual loads are lower than that. A 336' house that has at least some insulation probably has a cooling load of no more than 4000 BTU/hr, maybe 5000 BTU/hr if it has a single pane west-facing sliding door or only R13 in the attic (which is a comfort problem worth fixing if it's that poorly insulated.) Your heating load is probably also less than 5000BTU/hr.

A differentiating factor between models would be the MINIMUM modulated output rather than the maximum. The most efficient (and comfortable) operation of a variable speed "inverter drive" mini-split is when they are modulating at part load rather than cycling on/off at it's minimum speed. If you only need 5000 BTU/hr of cooling at design condition and the minimum modulated output is important- it's not going to be as efficient or comfortable as equipment that modulates down to ~1000 BTU/hr. So, the exact model matters- Gree makes at least 3-4 different 9000 BTU mini-splits.

The highest efficiency 9000 BTU Gree is the

CROWN 09HP , but it's priced, more like $1600, not $1200. ($1575 at eComfort) It has a lower minimum-modulation than most of their others at about 1500 BTU/hr, which isn't bad at all.

But that low min-output is is still not as low as the ~$1300

9000 BTU LG ArtCool Premier at ~1000 BTU/hr, and which also an even higher rated

heating efficiency than a Gree Crown despite 10% lower cooling efficiency.

The

Gree Terra is about the same money as the LG, but only modulates down to 3500 BTU/hr in cooling mode, 2200 BTU/hr in heating mode. The Terra has comparable in cooling efficiency to the ArtCool Premier, but 25% lower heating efficiency.

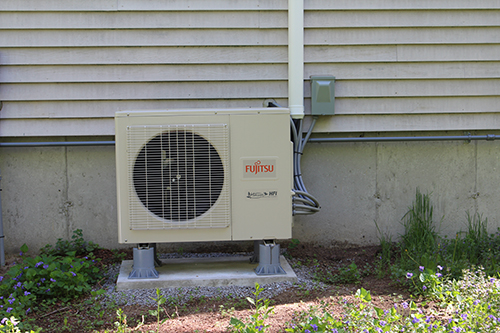

For first-tier Japanese mini-splits the Mitsubishi -FH09NA would be the ticket, due to it's ~1600 BTU/hr minimum output, which is lower than the Fujitsu & Daikin competition, priced at $1,629 at eComfort, more efficient than the Gree Crown, and only $54 more (at eComfort).

The recently released half-ton

Mitsubishi FH06NA could almost certainly cover the loads for a 336 square foot cottage, and it's even cheaper ( $1519 @ eComfort) , with the same ~1600 BTU/hr min-mod output numbers of the FH09NA.

So...

... if it were my project (which it isn't) I'd be inclined to go with the either half ton FH06 if going first-class, or the 3/4 ton LG LA090HYV1 if the $200-300 price difference was important for my budget, and not the Gree Terra, which has a minimum cooling output comparable to your design cooling load and would thus never actually modulate.