Killawhale

New Member

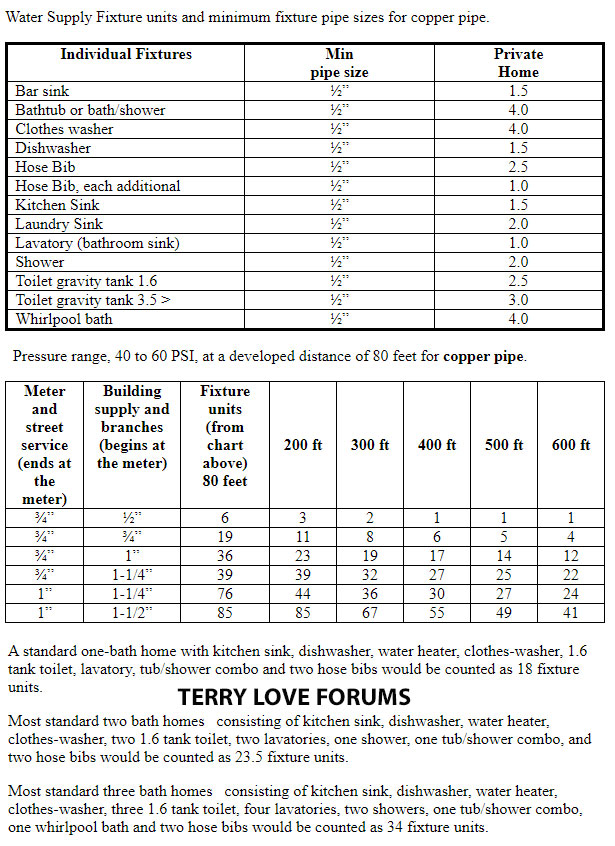

So I am building a shop/ apt, apt is 2bdrm 2 bath, and in the future building a 3bdrm/2.5 bath house on same property. I have asked around locally and get so many different answers. I want to plan for the future so what size main should i use. My initial idea was 2in to a Y then 1 1/4 to house and building. From street to Y is 900ish feet and 450+ to building and house site. City has 3/4 connection and 70+ psi of pressure. Thank you in advance