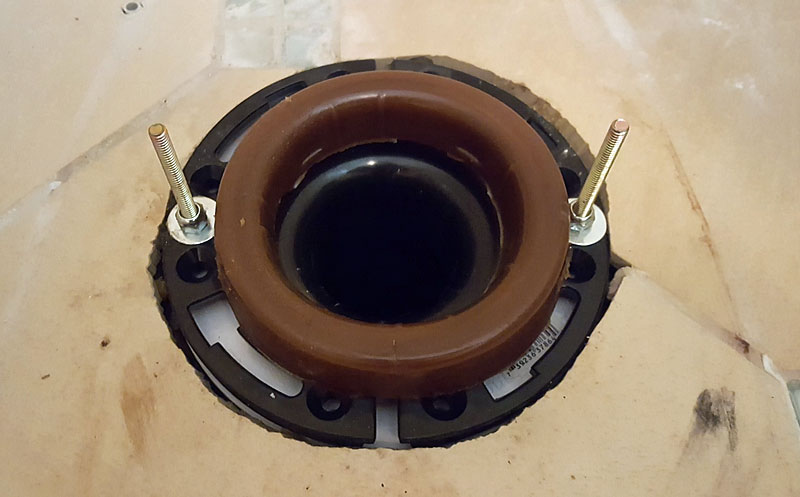

I removed a Toto toilet because of a gaseous smell to find several stacked wax rings and a flange recessed 1 1/2 inches below the tile in the concrete slab of our basement. The concrete was crudely cut out, but not enough to place spacers on top of the original flange. What is the best option going forward?

1. Use a Danco Perfect Seal

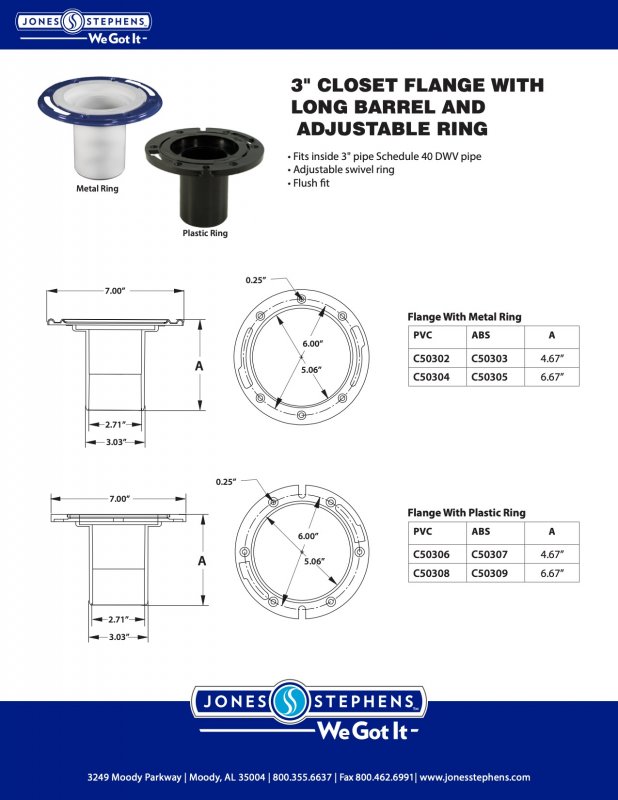

2. Cement a Jones Stevens Long Barrel Close Flange into the existing 3" PVC pipe

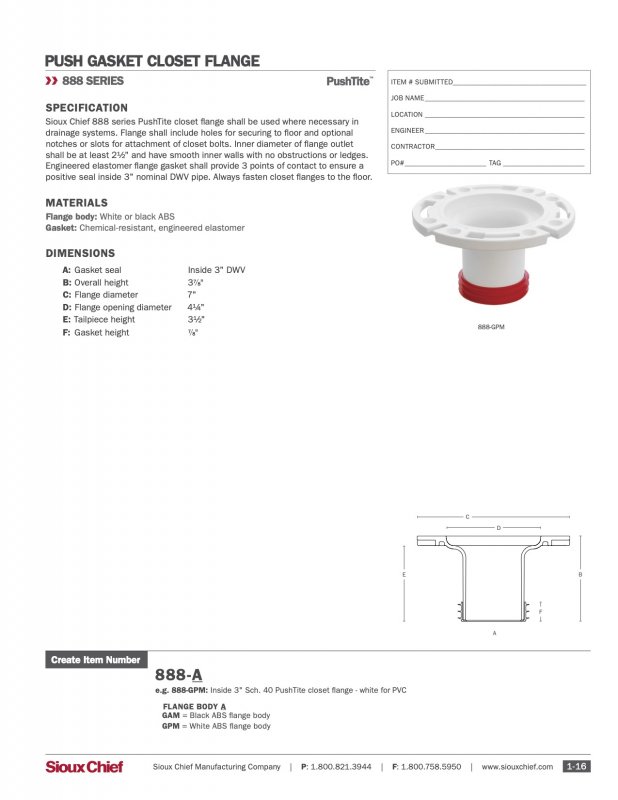

3. Use a Sioux Chief PushTite Closet Flange (888-GPM)

Other suggestions? Many Thank!

1. Use a Danco Perfect Seal

2. Cement a Jones Stevens Long Barrel Close Flange into the existing 3" PVC pipe

3. Use a Sioux Chief PushTite Closet Flange (888-GPM)

Other suggestions? Many Thank!