michaelmew

New Member

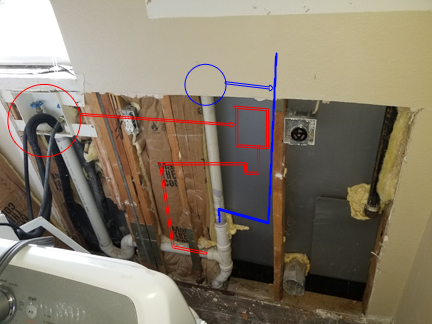

My wife wants me to convert our side by side W/D to stackable. No big deal, right? Just move the plumbing and electricity. Unfortunately, the original builders didn't leave me anything to work with before going into the slab. The existing tee is already reduced to 1 1/2" for the vent. So, I believe this means I need to re-route the vent as shown (in blue) so that I can tie-in with the existing 2" waste as shown (in red).

Stop me if I'm wrong, but assuming I'm on the right path, my questions are:

1. Is there a minimum vertical drop coming out of the washer drain outlet box before the p-trap?

2. Is there a min/max horizontal leg of the p-trap before it drops again?

3. For the (2) new waste elbows, regular 90 or long sweep 90? Does it even make a difference?

4. Will it vent and drain as shown?

5. For the (2) new vent elbows, regular 90 or long sweep 90?

The other question I have involves tapping into the existing gas line, which I will also be doing. Can someone tell me definitively whether or not a sediment trap is required on my new gas dryer? I am reading conflicting information. I am in Texas.

Thanks!

-mm

Stop me if I'm wrong, but assuming I'm on the right path, my questions are:

1. Is there a minimum vertical drop coming out of the washer drain outlet box before the p-trap?

2. Is there a min/max horizontal leg of the p-trap before it drops again?

3. For the (2) new waste elbows, regular 90 or long sweep 90? Does it even make a difference?

4. Will it vent and drain as shown?

5. For the (2) new vent elbows, regular 90 or long sweep 90?

The other question I have involves tapping into the existing gas line, which I will also be doing. Can someone tell me definitively whether or not a sediment trap is required on my new gas dryer? I am reading conflicting information. I am in Texas.

Thanks!

-mm