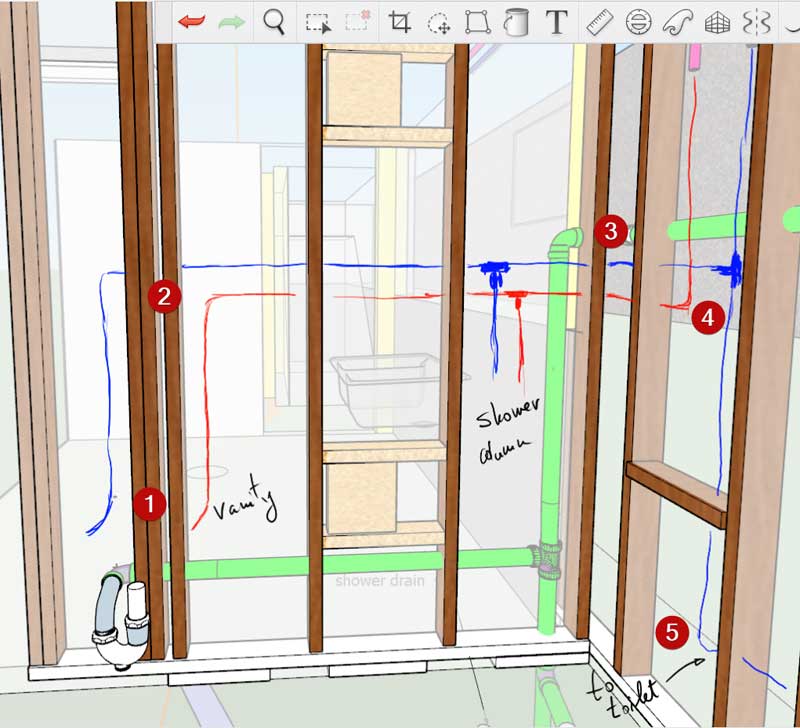

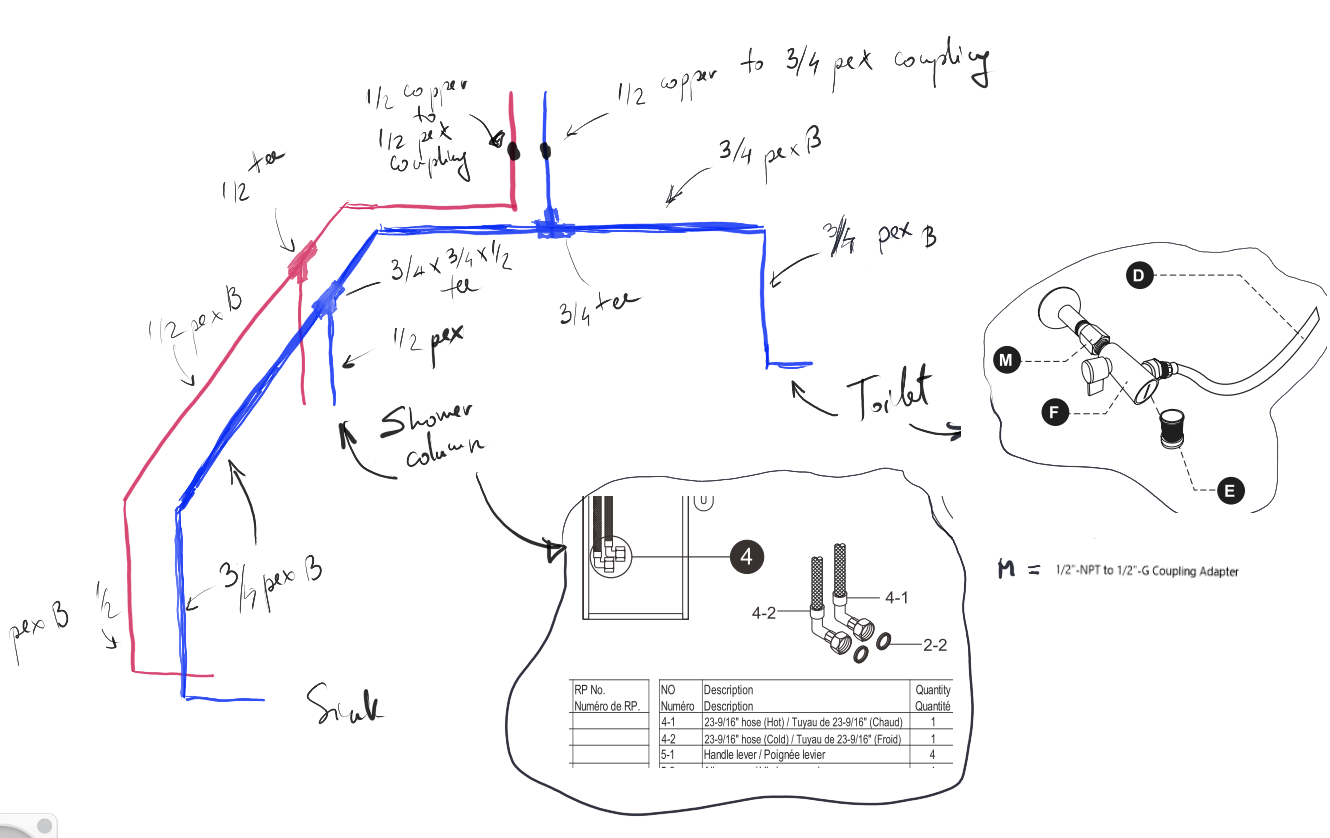

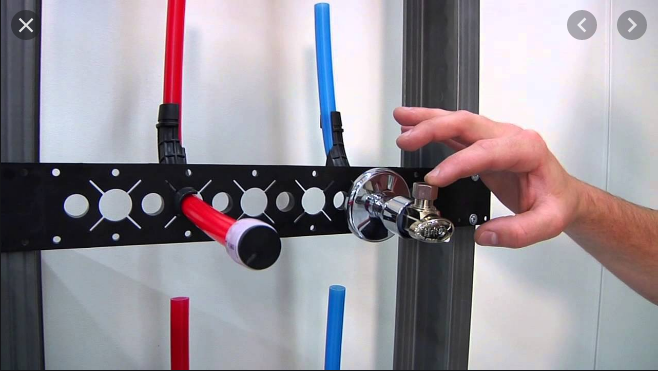

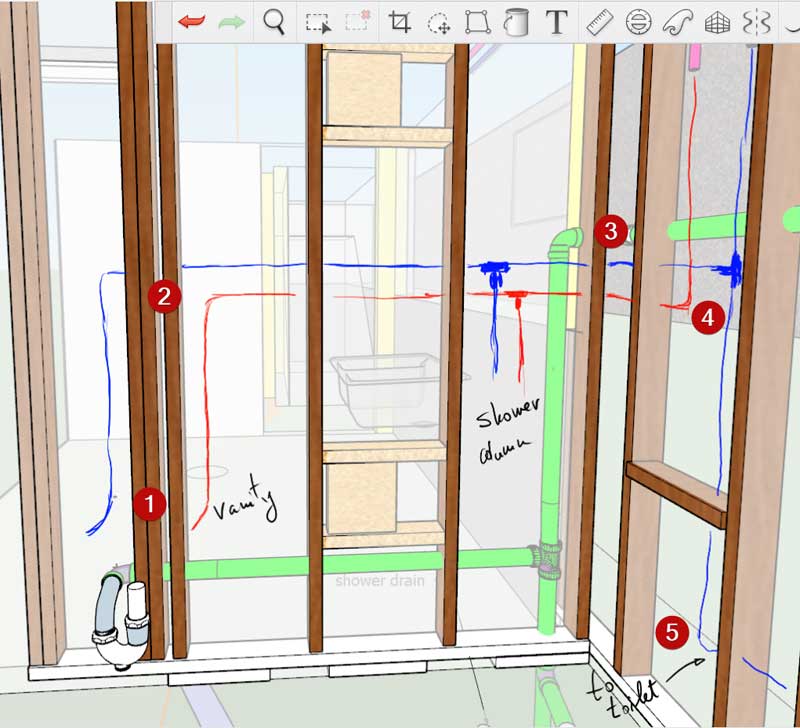

In the picture below I need to transition from copper to PEX (top right side of the picture) and the feed the vanity the shower column and the smart toilet.

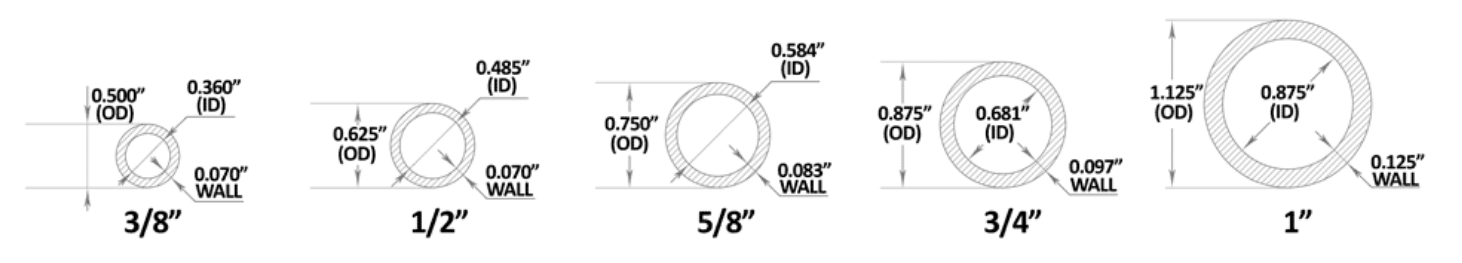

At a first sight, besides the two transition couplings, I would say I just need three Tees that the rest of them (1,2,3,4) could be bends with adequate support. The copper is 1/2 so I will transition to the same unless I am being told to use larger. Main supply is above, in the ceiling, that is where the to copper verticals at the top right side are coming from

At a first sight, besides the two transition couplings, I would say I just need three Tees that the rest of them (1,2,3,4) could be bends with adequate support. The copper is 1/2 so I will transition to the same unless I am being told to use larger. Main supply is above, in the ceiling, that is where the to copper verticals at the top right side are coming from