JohnfrWhipple

BATHROOM DESIGN & BUILD

Every day at the "Yacht Job" I learn so many things about building showers on a boat. There are a good 6-12 men working inside this 65' foot yacht and working conditions are tight - the bathrooms are small and the showers inside the "Heads" even smaller. I think the first shower I prepped had to be the smallest shower I have ever worked in.

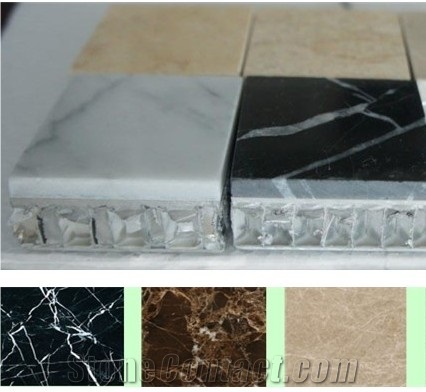

All three showers are getting Marble Tile. The marble will be large slabs but the slabs are super thin and light weight.

On the back side of these thin veneer slabs of marble is a heavy duty 1/8" thick piece of aluminium - or some other kind of light weight metal. I'm told that this micro slab (thickness is 3/8" not 3/4") is as strong as full slab but comes with a huge weight savings. The Question I have is how the hell do you cut and install these panels?

I'm heading back to boat on Tuesday and hope to leave with a sample of the stone. My guess would be to back cut the aluminmum with a No-Ferreous Saw Blade on say my skill saw and then top cut the marble with the diamond wet blade. Hmmm - Maybe that should be reversed in hind sight. Best to cut the marble and then the metal.

The crew that will install these panels specialize in light weight construction and have used this type of marble slabs in a few Airplane Projects. Ever since I heard this - I have a strong desire to build a luxury shower on a private plane! How cool would that be?

Better hurry up! I read that you only get five minutes in the shower per guest. I think their are 17 people in total on this planes first class lounge. Still would be fun to shower in the sky!!!

All three showers are getting Marble Tile. The marble will be large slabs but the slabs are super thin and light weight.

On the back side of these thin veneer slabs of marble is a heavy duty 1/8" thick piece of aluminium - or some other kind of light weight metal. I'm told that this micro slab (thickness is 3/8" not 3/4") is as strong as full slab but comes with a huge weight savings. The Question I have is how the hell do you cut and install these panels?

I'm heading back to boat on Tuesday and hope to leave with a sample of the stone. My guess would be to back cut the aluminmum with a No-Ferreous Saw Blade on say my skill saw and then top cut the marble with the diamond wet blade. Hmmm - Maybe that should be reversed in hind sight. Best to cut the marble and then the metal.

The crew that will install these panels specialize in light weight construction and have used this type of marble slabs in a few Airplane Projects. Ever since I heard this - I have a strong desire to build a luxury shower on a private plane! How cool would that be?

Better hurry up! I read that you only get five minutes in the shower per guest. I think their are 17 people in total on this planes first class lounge. Still would be fun to shower in the sky!!!

Last edited by a moderator: