Reicherb

Member

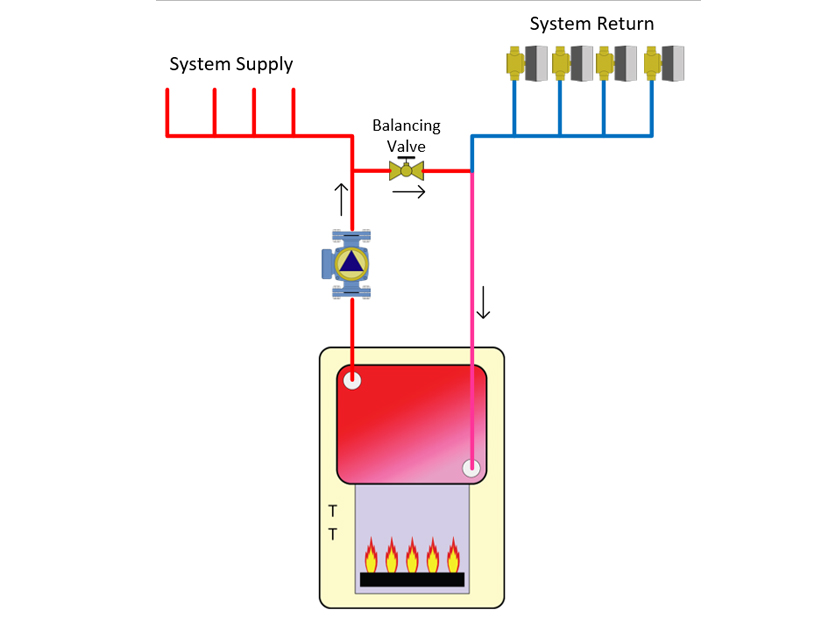

I installed a Weil McLain CGA2 and created 1 challenge and have a couple of other questions.

1. I created a "manifold" of sorts to distribute to the zone valves. If either of the bottom 2 zones are open, the top gets no heat... Why? Do I need to add balancing valves?

2. I didn't think about a low water cutoff. Is there a unit that you would recommend?

3. I want to set the water temp as low as possible but don't want to damage the heat exchanger. The manual says 130 degree return water minimum. Is that an absolute or is it more related to the temperature difference between the output and the return? I've currently got the boiler at 150 degrees. I'm sure that will be too low when winter arrives.

Attached are pictures.

Thanks,

Brad

1. I created a "manifold" of sorts to distribute to the zone valves. If either of the bottom 2 zones are open, the top gets no heat... Why? Do I need to add balancing valves?

2. I didn't think about a low water cutoff. Is there a unit that you would recommend?

3. I want to set the water temp as low as possible but don't want to damage the heat exchanger. The manual says 130 degree return water minimum. Is that an absolute or is it more related to the temperature difference between the output and the return? I've currently got the boiler at 150 degrees. I'm sure that will be too low when winter arrives.

Attached are pictures.

Thanks,

Brad