Joe V

New Member

I found slight leaks around cold side input of our water heater. This input has T style connectors where the expansion tank is connected to horizontal portion. I couldn't turn it enough to make it tight because that requires turning the whole T with expansion tank. That wasn't possible. So I removed the expansion tank and then unscrewed the T setup. Cleaned up the whole thing and now I am ready to install it.

Attached is picture of it soaking in vinegar liquid to get rid of gunk in the threads.

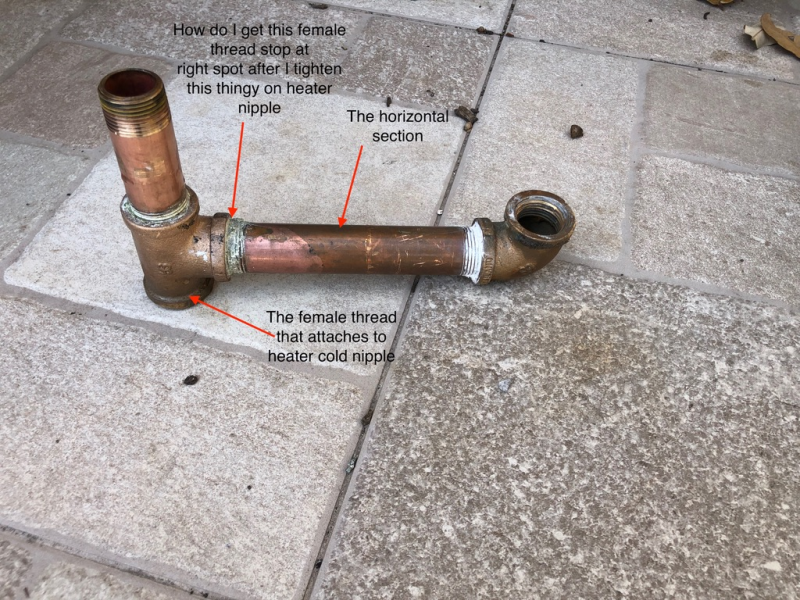

I attached second picture with my question as the description below may be too verbose to understand.

I want to unscrew the horizontal section from the T that goes to the expansion tank first. Then screw the vertical section on to cold input of water heater. This is where I need help what the tricks are. As you see, the horizontal pipe has to be screwed into the vertical section so that it points to the open area above tank for attaching expansion tank.

But when you start turning the vertical pipe, how do you start it so that the female pipe thread that the horizontal section threads into ends up at the right spot?

I want the vertical section be tight to prevent future leaks plus the female thread portion stop at right location for horizontal pipe to be fit in later.

The experienced installers probably have ways to do this right. I am wondering what those tricks are.

Thanks

Attached is picture of it soaking in vinegar liquid to get rid of gunk in the threads.

I attached second picture with my question as the description below may be too verbose to understand.

I want to unscrew the horizontal section from the T that goes to the expansion tank first. Then screw the vertical section on to cold input of water heater. This is where I need help what the tricks are. As you see, the horizontal pipe has to be screwed into the vertical section so that it points to the open area above tank for attaching expansion tank.

But when you start turning the vertical pipe, how do you start it so that the female pipe thread that the horizontal section threads into ends up at the right spot?

I want the vertical section be tight to prevent future leaks plus the female thread portion stop at right location for horizontal pipe to be fit in later.

The experienced installers probably have ways to do this right. I am wondering what those tricks are.

Thanks