Thomas K

Member

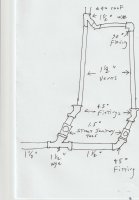

This is configuration I will be going with. Either that or cut cast iron and install 2" sanitary tee lower.

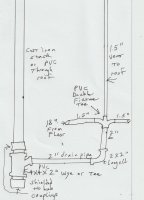

I have this irrational obsession with wanting to cut that cast iron stack below the 1.5" drain tee we've been discussing and replace everything from there through the roof with PVC.

Someone please tell me what a mistake I would be making and how I would destroy the vent stack flashing on the roof by dropping that cast iron through it. Besides the fact I would have to remove it in 4-5 cut up sections.

I have this irrational obsession with wanting to cut that cast iron stack below the 1.5" drain tee we've been discussing and replace everything from there through the roof with PVC.

Someone please tell me what a mistake I would be making and how I would destroy the vent stack flashing on the roof by dropping that cast iron through it. Besides the fact I would have to remove it in 4-5 cut up sections.

Attachments

Last edited: